-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Adventures in 3D printing

- Thread starter koenbro

- Start date

- Joined

- Feb 23, 2016

- Messages

- 424

This weekend I printed 90-degree elbows to help lift the transmission breathers on my truck. Long story short the front diff and the transfer case breathers are elevated from the factory into the engine compartment, but the rear diff and the transmission are not. The rear was easy to do and needed no printing.

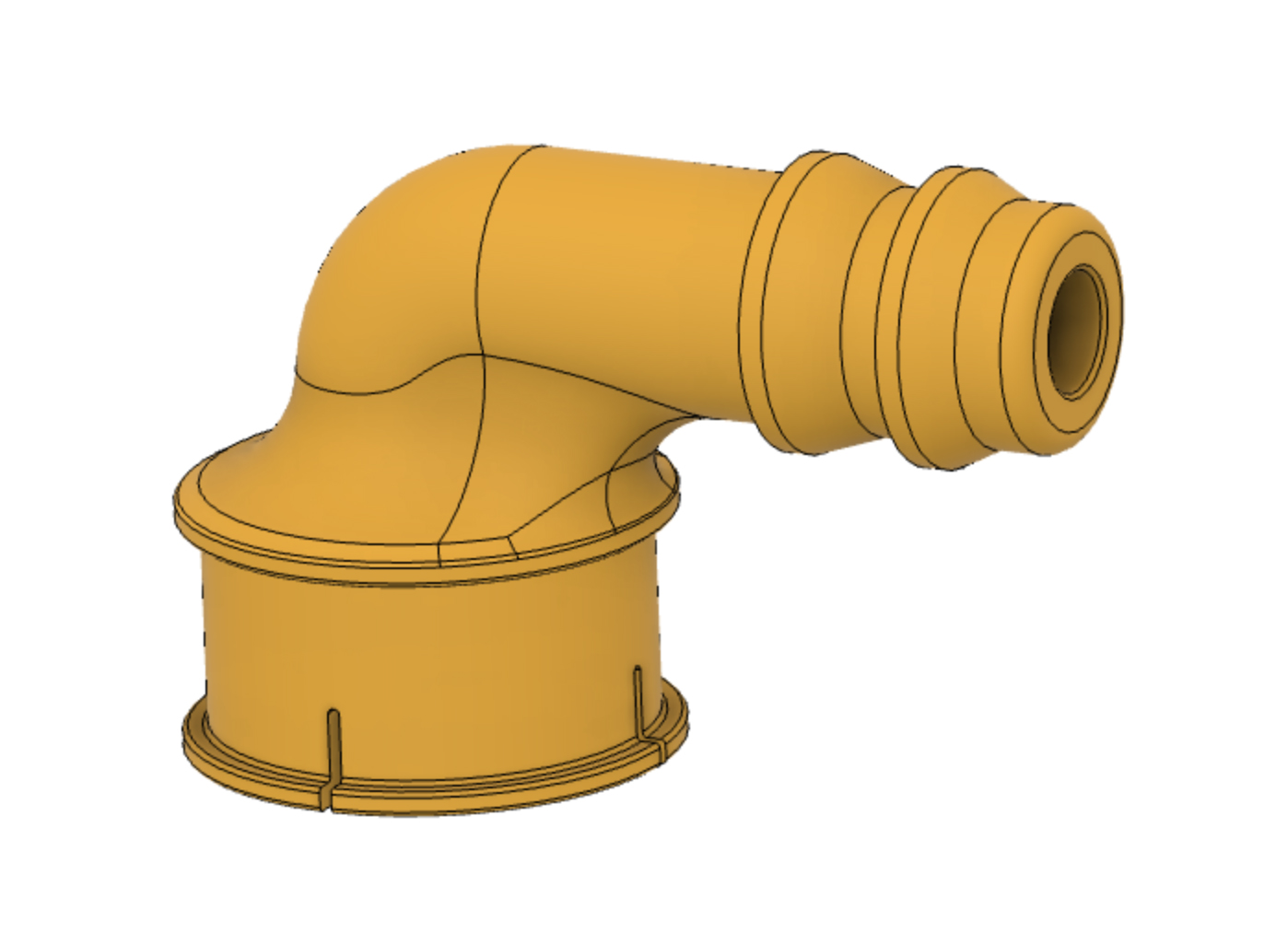

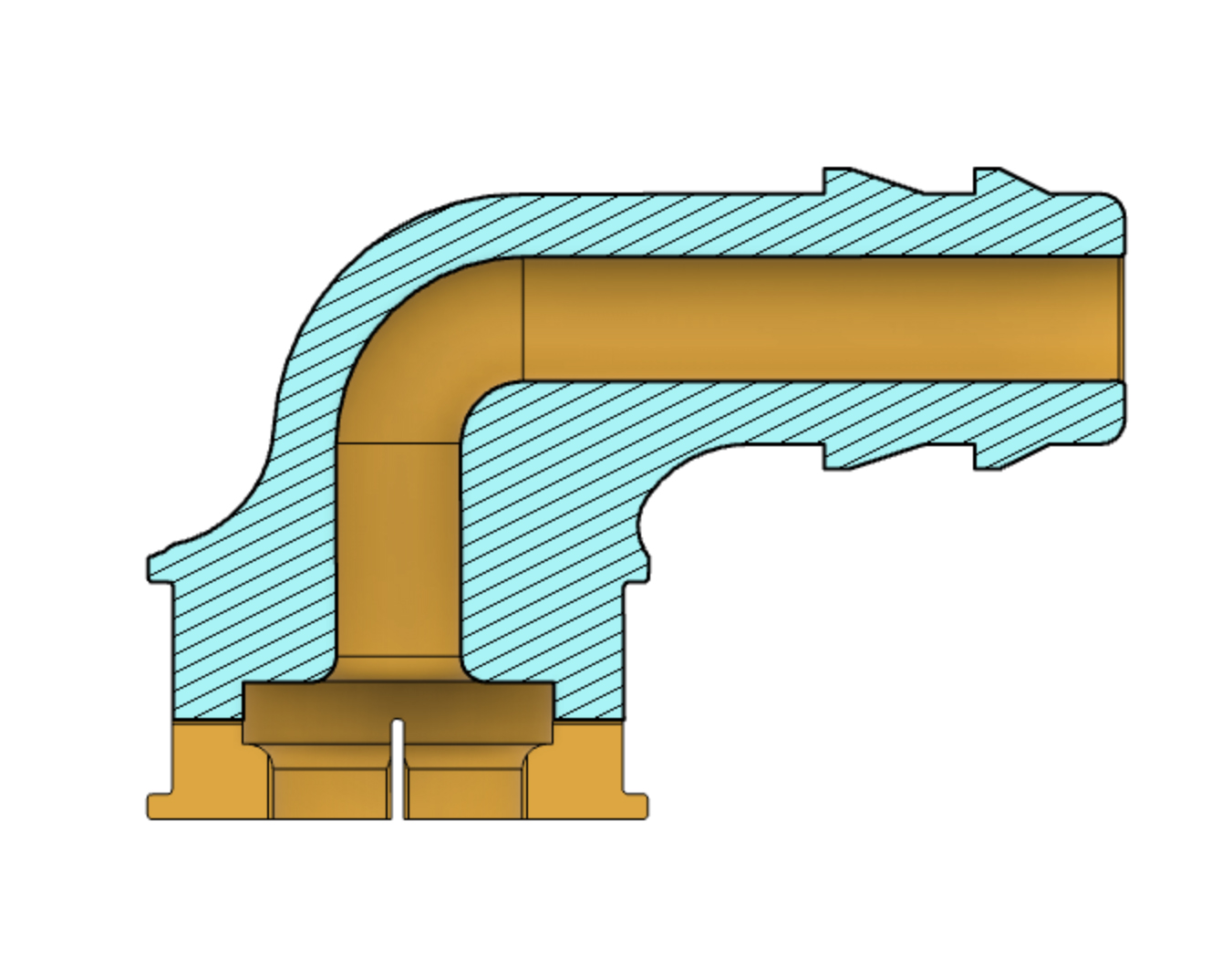

This project is about the transmission, which has not one, but two breathers. After popping the cap off there is an 11 mm OD nipple about 5 mm high, so one cannot just easily clamp a hose onto it.

So I designed a 90-degree elbow with a barbed end for 3/8" ID hose. The other end pops unto the transmission body nipple.

I took advantage of a groove on the nipple, so this adaptor pops unto the nipple and is held in place.

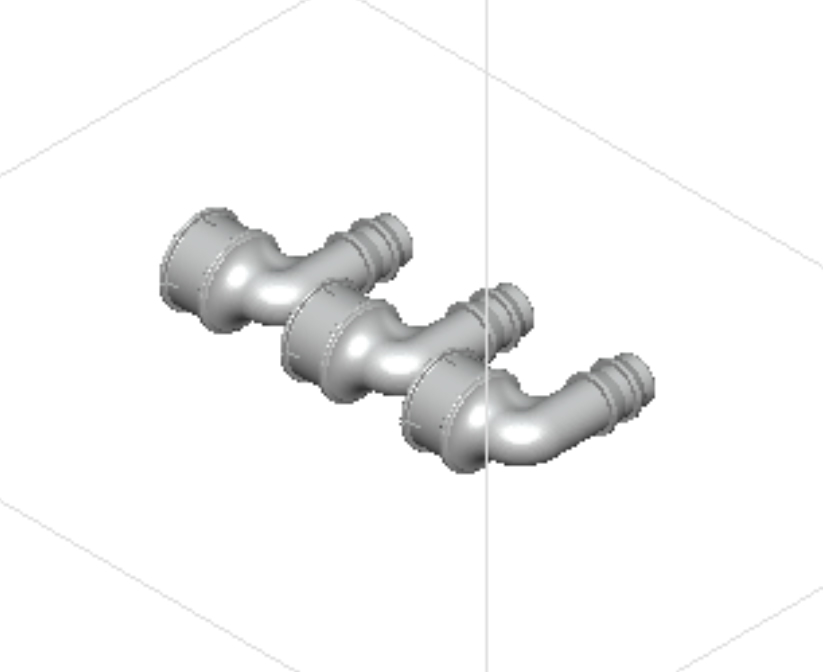

I printed three of them (in case one breaks during install) sideways so they are strong and not shear off.

They came out great and with a firm push popped unto the nipple but still rotated.

Once clamped down they don't move and will likely be water tight for this application.

Material: Nylon CF 12

This project is about the transmission, which has not one, but two breathers. After popping the cap off there is an 11 mm OD nipple about 5 mm high, so one cannot just easily clamp a hose onto it.

So I designed a 90-degree elbow with a barbed end for 3/8" ID hose. The other end pops unto the transmission body nipple.

I took advantage of a groove on the nipple, so this adaptor pops unto the nipple and is held in place.

I printed three of them (in case one breaks during install) sideways so they are strong and not shear off.

They came out great and with a firm push popped unto the nipple but still rotated.

Once clamped down they don't move and will likely be water tight for this application.

Material: Nylon CF 12

- Joined

- Feb 23, 2016

- Messages

- 424

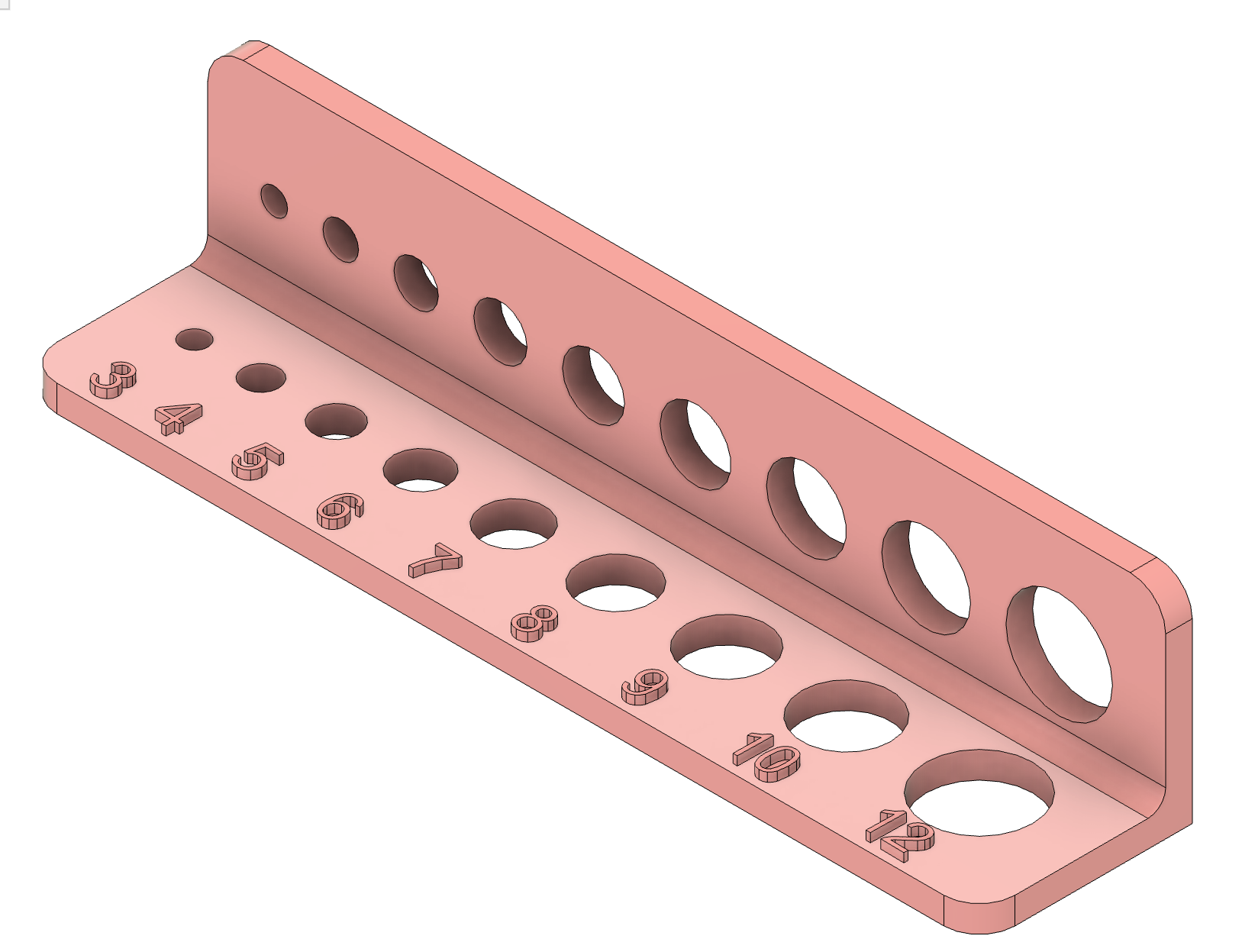

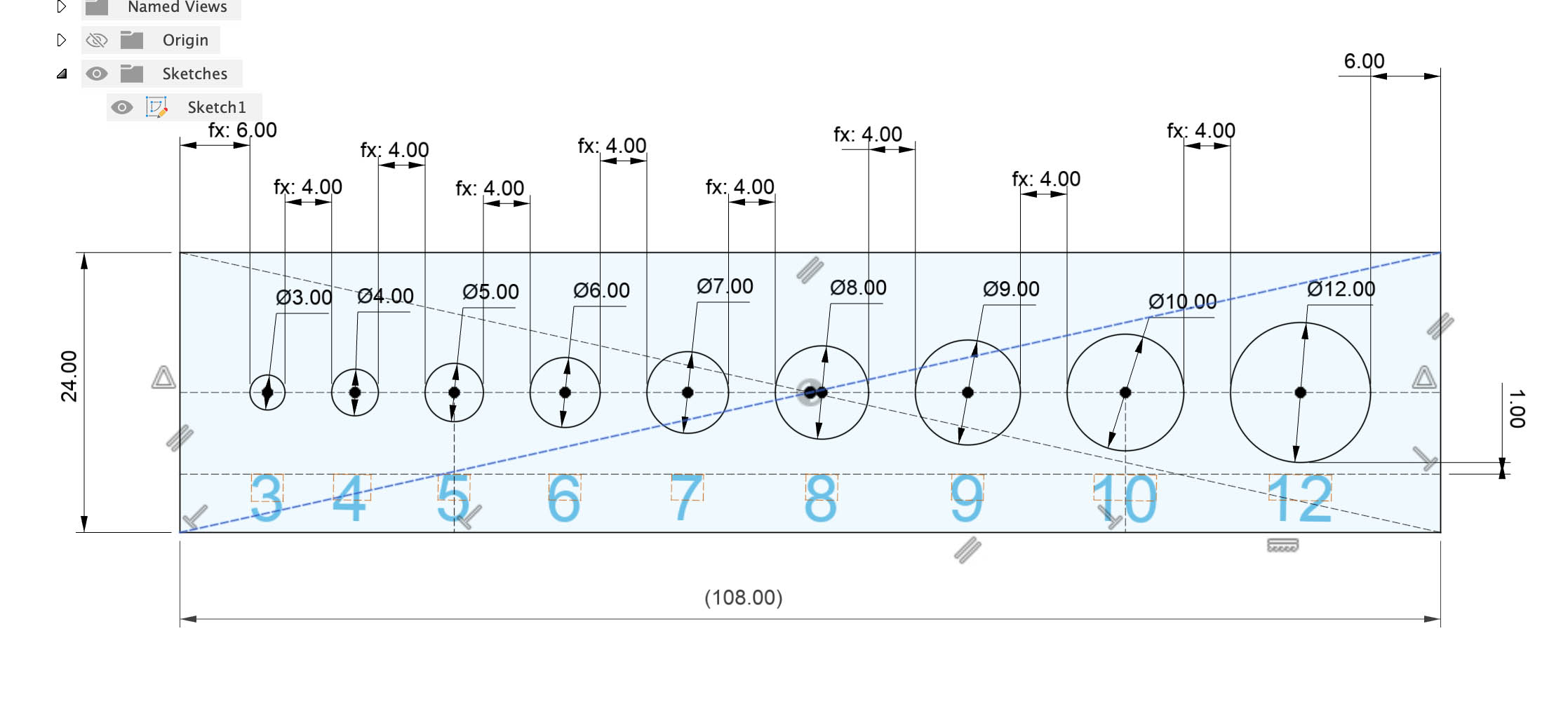

Wanted to test the internal dimensional accuracy of my printer. External accuracy is usually less critical and is within 0.5mm anyways, but internal dimensions have tripped me up occasionally. So here is an experiment:

The numbers are 4mm tall and 1mm proud from the surface. Wall thickness 3mm. Will show results once the print is dried etc. This design will show if there is a difference between horizontally and vertically printed holes.

The numbers are 4mm tall and 1mm proud from the surface. Wall thickness 3mm. Will show results once the print is dried etc. This design will show if there is a difference between horizontally and vertically printed holes.

Last edited:

- Joined

- Jan 20, 2021

- Messages

- 296

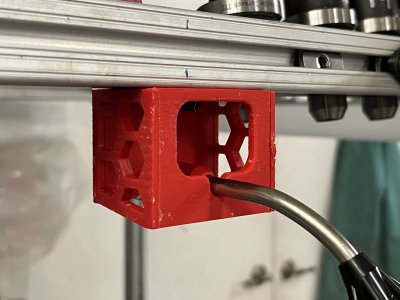

Nice work on the WMPG cradle. I had to replace one recently. It never fell. I'm not sure what the deal was, the wheel stopped working. I have 3 Centroid machines with the wireless MPG's. Wouldn't be without them!

- Joined

- Feb 23, 2016

- Messages

- 424

I could not measure the small holes, lacking reliable stepwise gauges (drills are hit or miss) but found that the larger holes were about 2 percent undersized. The 3mm was about 10% undersized.

So I am going to oversize my openings by about that much unless I want a bit of a snap-in fit. Sorry I realize it is not a scientific test, but it's the best I could.