-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

A New Home for my Karl Benz Engine

- Thread starter rdean

- Start date

- Joined

- Feb 2, 2014

- Messages

- 1,208

Robert there are several Benz models on the internet that are much nicer than mine but thank you for your kind words anyway.

I dought they would be interested.

I added some rounded corners and smoothed over the top and then put a clear finish on the seat.

I cut the floor boards and checked for fit.

Looks like they will work out well.

They will be removed, sanded, stained, and sprayed with clear coat before final assembly.

Thanks for looking

Ray

I dought they would be interested.

I added some rounded corners and smoothed over the top and then put a clear finish on the seat.

I cut the floor boards and checked for fit.

Looks like they will work out well.

They will be removed, sanded, stained, and sprayed with clear coat before final assembly.

Thanks for looking

Ray

- Joined

- Feb 2, 2014

- Messages

- 1,208

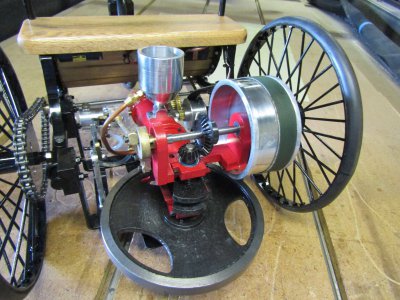

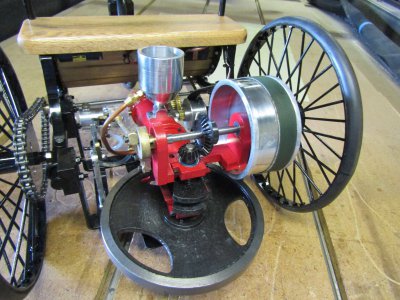

I added a back rest to the seat for looks and drilled and tapped the two drive sprockets for set screws.

My friend Chris gave me a piece of used belting that he had replaced on his lathe. It was too wide but I was able to tear it length wise and the tear followed the fabric very nicely.

I used some Alligator splices to make up the ends. They were size 00 the smallest the factory made and just the right size for the Benz.

I left the belt quite long to act as a clutch for the engine.

I mounted the carb mixture valve where I could get to it easily.

I thought I should start the engine and work out any issues now rather than later. After a few minutes of hand cranking and a little cussing I have the engine running nicely like it was.

I have had some worries that the engine would not have enough power to pull the Benz and just bog down. The Benz weighs in at just under 25 pounds now so I gave it a try on the cement slab outside my shop. Now the drive belt is very loose and I didn't expect it move much as I would rather have had it just sit still. Well it took off at a rather quick pace without a noticeable drop in engine RPMs. I didn't have to run to catch up but I think it will be faster than I would like it to be.

Things left to do:

Make a proper clutch.

A steerable front wheel.

Maybe larger driven sprockets for the rear wheels to slow it down some.

A differential may still be needed for turning.

Thanks for looking

Ray

My friend Chris gave me a piece of used belting that he had replaced on his lathe. It was too wide but I was able to tear it length wise and the tear followed the fabric very nicely.

I used some Alligator splices to make up the ends. They were size 00 the smallest the factory made and just the right size for the Benz.

I left the belt quite long to act as a clutch for the engine.

I mounted the carb mixture valve where I could get to it easily.

I thought I should start the engine and work out any issues now rather than later. After a few minutes of hand cranking and a little cussing I have the engine running nicely like it was.

I have had some worries that the engine would not have enough power to pull the Benz and just bog down. The Benz weighs in at just under 25 pounds now so I gave it a try on the cement slab outside my shop. Now the drive belt is very loose and I didn't expect it move much as I would rather have had it just sit still. Well it took off at a rather quick pace without a noticeable drop in engine RPMs. I didn't have to run to catch up but I think it will be faster than I would like it to be.

Things left to do:

Make a proper clutch.

A steerable front wheel.

Maybe larger driven sprockets for the rear wheels to slow it down some.

A differential may still be needed for turning.

Thanks for looking

Ray

- Joined

- Feb 2, 2014

- Messages

- 1,208

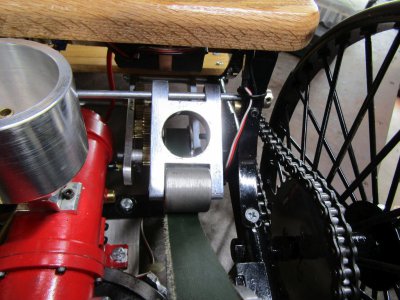

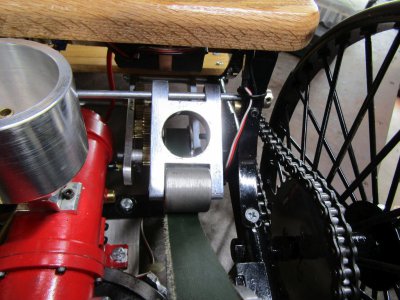

I have the clutch (belt tightener) built and installed. The lever works just backwards of the Benz with the lever back for forward drive.

When I moved the engine back 2 inches a while back I used two steel plates that were bolted to the two frame brackets.

I found that there was too much flex in the plates the way they were mounted and allowed the engine to buck up and down as it was running.

I replaced them with a single longer plate of 1/2" aluminum and that took care of that.

As I am working on the final details I have found the gear ratio is just too high. With the tightener engaged so the belt doesn't slip the engine can not pull the Benz. If it could it would be moving at a fast walking speed which is not acceptable.

I will be giving this some extra thought before I change anything.

Thanks for looking

Ray

When I moved the engine back 2 inches a while back I used two steel plates that were bolted to the two frame brackets.

I found that there was too much flex in the plates the way they were mounted and allowed the engine to buck up and down as it was running.

I replaced them with a single longer plate of 1/2" aluminum and that took care of that.

As I am working on the final details I have found the gear ratio is just too high. With the tightener engaged so the belt doesn't slip the engine can not pull the Benz. If it could it would be moving at a fast walking speed which is not acceptable.

I will be giving this some extra thought before I change anything.

Thanks for looking

Ray

- Joined

- Feb 2, 2014

- Messages

- 1,208

I have decided to change the big output pulley on the cam shaft to lower the speed. The original was 4" in diameter and the new pulley is 2.5" in diameter. That should make a big difference.

I had to make a shorter belt and a larger tightener roller and modify the roller bracket for the clutch to work.

Please excuse the video quality.

Have you ever tried to make a video by yourself while on the ground on all fours and then quickly get up and try to focus the camera. Then in the bright sunlight I couldn't see the view screen and just had to guess where the Benz was. Well it didn't turn out too badly so here it is.

I call this officially done.

Thanks to all that followed along.

Ray

I had to make a shorter belt and a larger tightener roller and modify the roller bracket for the clutch to work.

Please excuse the video quality.

Have you ever tried to make a video by yourself while on the ground on all fours and then quickly get up and try to focus the camera. Then in the bright sunlight I couldn't see the view screen and just had to guess where the Benz was. Well it didn't turn out too badly so here it is.

I call this officially done.

Thanks to all that followed along.

Ray