- Joined

- May 7, 2023

- Messages

- 1,387

$275USD is $416AUD and that's before shipping. And that PF is too large for his mill.

The LMS version is the one that fits his mill and it's $400 USD which is $600AUD

I have zero reason to dispute his AUD pricing.

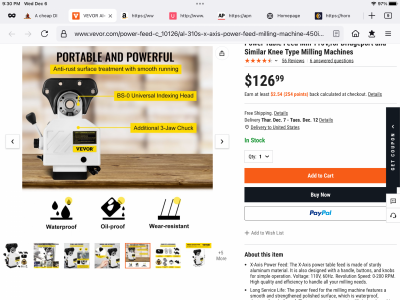

Man, thats cheap enough I might buy one for my mill at work.Here's the least expensive power feed I've found:

VEVOR X-Axis Power Feed for Milling Machine, 450 in-lb Torque, 0-200RPM Adjustable Rotate Speed 120V Power Table Feed Mill Feeder, for Bridgeport Some Knee Type Mills with a 5/8" End Shaft Diameter | VEVOR US

Discover VEVOR X-Axis Power Feed for Milling Machine, 450 in-lb Torque, 0-200RPM Adjustable Rotate Speed 120V Power Table Feed Mill Feeder, for Bridgeport Some Knee Type Mills with a 5/8" End Shaft Diameter, Compact & Versatile and Sturdy & Stable at lowest price, 2days delivery, 30days returns.www.vevor.com

I've purchased a few other Vevor products like a sauna heater, an ultrasonic cleaner and a bathroom towel heater, and all have been very well executed in design and manufacturing. I've gotten two of these power feeds for about $125, free shipping, and adapted them to moving the head and table of my Rockwell EFI drill press. They work great and I recommend them. Same crummy instructions as the expensive brands.

The first power feed of the classical design like these came on my mill 15 years ago, and broke maybe 10 years ago. I took it apart and was stunned at the mess of parts inside, threw it away and bought a $400 replacement that has been working fine since. I added a Z axis drive, and installed a couple other X drives for friends. Eventually I learned how they actually work, which is a combination of clever and appalling design, but once understood works OK.

A tricky part of the design is to prevent over travel of the internal switching, a roll pin protrudes from the case under the forward/reverse handle and rides in a routed groove in the back of the handle hub. If the handle is rotated just a bit farther than that limit, it can mechanically disconnect internally or even break an internal bracket. I learned this when trying to make the handle work 90 degrees clockwise from normal to be up/down instead of left/right.

Fun fact:

If you open the back cover on these there is a spare part inside. I disremember what it was, shear pin? Fuse? something minor, but it surprised me that it was included.