U

umahunter

Forum Guest

Register Today

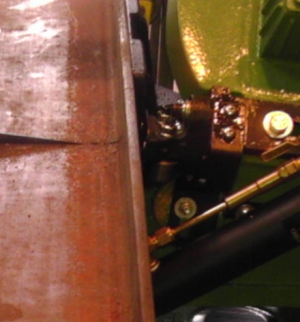

I find myself cutting a lot of aluminum lately and am realizing I need a blade cleaner having coolant would be great but it's not an option at the moment so I figured I'd make a cleaner wondering what's worked for others pics would be nice