- Joined

- Aug 24, 2013

- Messages

- 29

So Wednesday I go to the local steel supplier and ask for a 2' long piece of 1 1/8" 4140 round rod. The supplier said, I don't have any in stock, but cold roll is the same thing. That's when I should have walked away, but having been told he was a stand up guy I didn't. He said he had a truck coming in tomorrow and could order the 4140 today. Since this was my first ever purchase of 4140 I said ok.

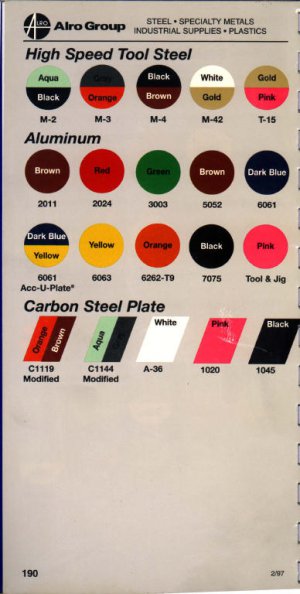

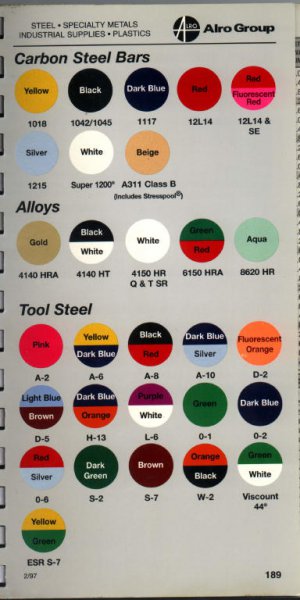

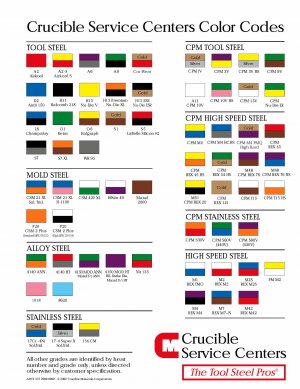

So Thursday I get a call to go pickup the order. It was painted a couple colors and cost $53.33 I get it home and put it in the lathe and hit it with 150 grit sand paper. The paint came off and the bar had a thick coat of rust on it. Just about then my son-in-law arrives with a 2' long piece of 3" 4140 round rod he picked up in the next town. It was marked 4140 and was nice and shiny and he paid $42.50.

The 3" 4140 when hit with a hammer had a nice ring to it and the 1 1/8" 4140 had a thud to it when it was hit with a hammer.

The 3" inch 4140 when filed barely made a mark while the rusty 4140 was much softer.

Obviously he took one look at me and new I just fell off the turnip truck on the way into town. Long winded story to get to the question. Does 4140 rust as bad as cold roll or does it stay shiny?

So Thursday I get a call to go pickup the order. It was painted a couple colors and cost $53.33 I get it home and put it in the lathe and hit it with 150 grit sand paper. The paint came off and the bar had a thick coat of rust on it. Just about then my son-in-law arrives with a 2' long piece of 3" 4140 round rod he picked up in the next town. It was marked 4140 and was nice and shiny and he paid $42.50.

The 3" 4140 when hit with a hammer had a nice ring to it and the 1 1/8" 4140 had a thud to it when it was hit with a hammer.

The 3" inch 4140 when filed barely made a mark while the rusty 4140 was much softer.

Obviously he took one look at me and new I just fell off the turnip truck on the way into town. Long winded story to get to the question. Does 4140 rust as bad as cold roll or does it stay shiny?