- Joined

- Mar 25, 2013

- Messages

- 4,617

Thanks! Yes I have seen that method. Can I ask you where you got that grinding wheel and what type?I posted a while back about grinding my 4-jaw chuck. You can check it out here:

Replacement 3 jaw lathe chucks

Greetings folks, I am having to replace my Atlas 12 inch Pedestal Lathe mod 3996 3 jaw chuck.....The chuck will not keep the work piece tight in the jaws.....I am wondering where you folks have gone to buy tooling or would go to find a good (hobby style) chuck that will not brake the...www.hobby-machinist.com

Ted

My current plan is to rough grind the jaw on my disc sander (cringe) to get it flat and then use a diamond wheel in my mill to finish grind. I would prefer the jaws flat rather than concave like your method yields. Your method may be my fall back move!

At this point the chuck is only good as an anchor for my fishing boat and not great for that either. I am now trying to figure the optimal way to grind it.

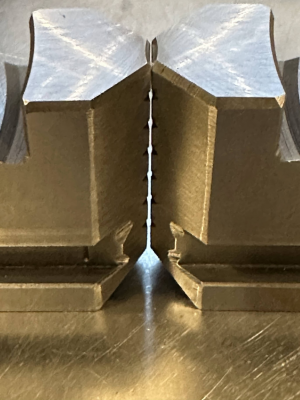

Bad:

Last edited: