- Joined

- Mar 25, 2013

- Messages

- 4,617

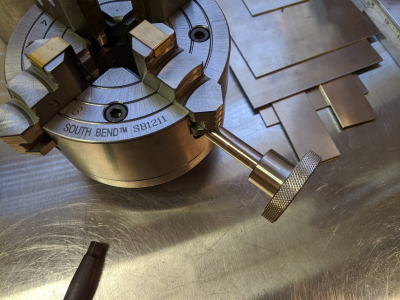

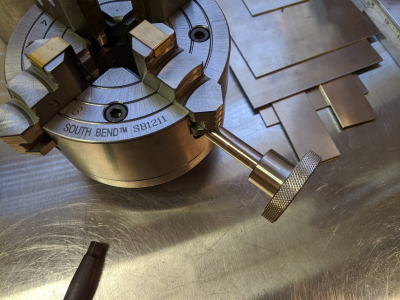

I need help getting a quality 4 jaw independent chuck set up on my SouthBend (Grizzly) 10K lathe. There are a lot of issues. Let me start with the chuck I have.

This is a new model SB chuck that is ofhigh quality made in Taiwan.

The jaws are very tight with no slop. The grind appears to be of high quality. It came with a factory D1-3 back plate that fits perfectly and runs true.

It seems whenever I clamp a round workpiece in this chuck the work is crooked with respect to the axis of the spindle. Obviously the radial runout is adjustable but shouldn't this align the stock to the axis? I can bang it around with a mallet and an indicator and eventually get it straight but this inevitably damages the work piece. Yes, brass shims and all that but I never have this issue with 3 jaws on this machine or with other 4 jaws I have used in the past. It seems like the grind of the jaw teeth is very sharp and too sharp to allow the stock to move straight when clamped. It just digs into the work. Am I confused about this? It also occurs to me that the jaws could be ground wrong with a conical or reverse conical grind?

Should I try to regrind the jaws?

I wanted to get a Bison but the 6" has a 2.75" bolt hole circle which cannot be used (easily) with a D1-3 back plate. I know that Monarchs have a D1-3 setup. What 4 jaw do they use?

I am willing to entertain all suggestions from operator error to regrinding the jaws to buying a new chuck if I can find a good one that fits.

Have you experienced this problem?

This is a new model SB chuck that is of

The jaws are very tight with no slop. The grind appears to be of high quality. It came with a factory D1-3 back plate that fits perfectly and runs true.

It seems whenever I clamp a round workpiece in this chuck the work is crooked with respect to the axis of the spindle. Obviously the radial runout is adjustable but shouldn't this align the stock to the axis? I can bang it around with a mallet and an indicator and eventually get it straight but this inevitably damages the work piece. Yes, brass shims and all that but I never have this issue with 3 jaws on this machine or with other 4 jaws I have used in the past. It seems like the grind of the jaw teeth is very sharp and too sharp to allow the stock to move straight when clamped. It just digs into the work. Am I confused about this? It also occurs to me that the jaws could be ground wrong with a conical or reverse conical grind?

Should I try to regrind the jaws?

I wanted to get a Bison but the 6" has a 2.75" bolt hole circle which cannot be used (easily) with a D1-3 back plate. I know that Monarchs have a D1-3 setup. What 4 jaw do they use?

I am willing to entertain all suggestions from operator error to regrinding the jaws to buying a new chuck if I can find a good one that fits.

Have you experienced this problem?

Last edited: