B

BRIAN

Forum Guest

Register Today

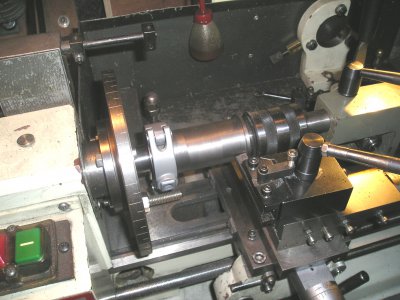

The replacement material arrived yesterday, so today I have been up to my ankles in chips.

Ain't life just great, when you are having fun.

Brian.

Ain't life just great, when you are having fun.

Brian.