Did a little investigating this morning and found out SB lathes move the carriage 4 ins per revolution of the dialThe chart I posted is right out of the How to Run A Lathe booklet from South Bend, so it will work for all SB lathes out there. I'm not positive that it will work for other lathes from other manufacturers.

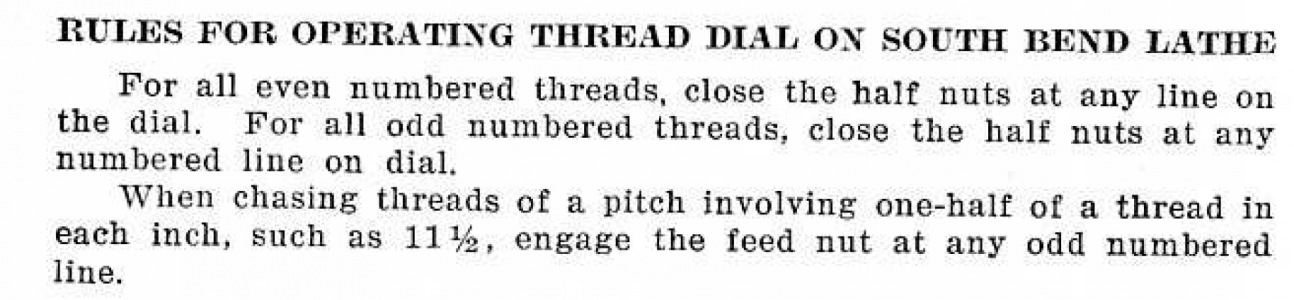

I reworded some of the text to make it clearer (for me) to understand.

I printed out the .pdf version, took it down to Office Depot and had it laminated, then posted it above my lathe.

My lathe only moves 3 ins

Thought they were created equal was wrong