Single phase 220 is actually just two 120V phases 180 degrees out of sync. Between the two hot wires, you get 220V. Either one to ground will get you 120V. Newer equipment gets angry if you do that, and wants a dedicated neutral for 120V. And it did create a shock hazard as "ground" could actually have some stray voltage on it. But in your panel, neutral and ground are connected. Just don't treat them as the same thing, or you create the possible safety hazard they added the separate line to fix. That was a bit long-winded to say what amounted to "because it's AC" I guess, but you seem the type that likes to get info.

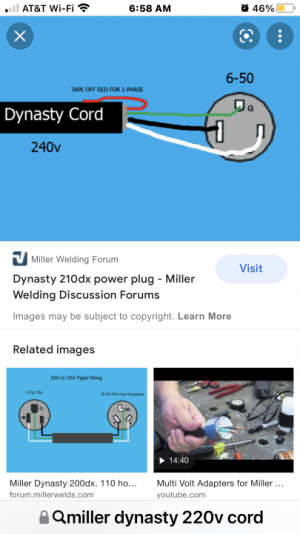

220V like this doesn't need a neutral and current flows basically between the two phase wires. It doesn't "need" ground either, but ground is included for safety. You connect the metal case of the equipment to ground, and any stray voltage flows there instead of into the unwary person touching it.

It's a bit oversimplified, but you don't need all that just to connect a welder safely.

3 phase is each phase 120 degrees off from the next. It works similarly between phases, but they way the motors work is that alternating poles are on different phases, so the magnetic field is almost rotating itself around the motor. Switching two wires changes the relationship, making the motor spin the other way. Again, simplified, and I'm not positive I totally understand it. Tesla, I am not.

"Brushless DC" motors are just 3 phase motors. The marketing folks got involved. The 3 phase wires are usually just L1/L2/L3, and your lathe likely just swapped two of them around when you did that. Same thing, just more complex switching setups.

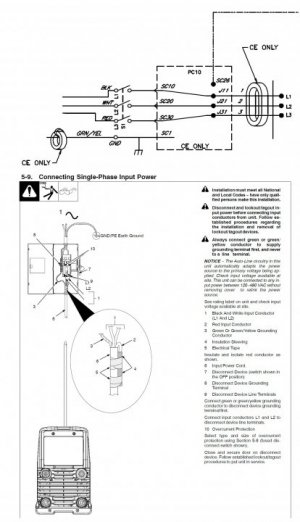

There is some risk to the welder, but it's quite low. In theory, running hot to the ground side could cause a problem. But if you follow the directions using the color codes, you'll be fine. And better manufacturers would design fail-safe setups to prevent it. I can't imagine Miller didn't. If it's rated for 220V/45A single phase, I wouldn't bother with setting it up for 3 phase input. That's a pretty commonly available setup. I would guess they included 3 phase input as an option for industrial users for convenience. I suspect inverter welders work like VFDs, converting it into a strong DC source, then using switching transistors to create the output.

It's pretty common for multi-input devices like that to not include plugs. There is little standardization for plugs in this range, so they often just have the user source whatever they need for their shop. I might worry that an import machine would have incorrect colors, but Miller wouldn't do that. If for no other reason than the liability it would create would be shut down by the legal department. The lawyers cost a lot more than the right wire.