- Joined

- May 18, 2014

- Messages

- 7

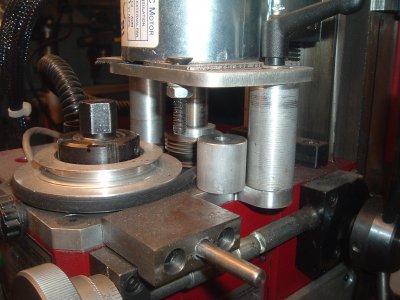

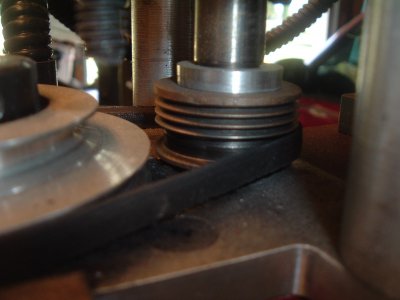

Well I piled up the gear box in my mini mill the other day and was looking at belt drive kits for 130 bucks there pretty expencive so my brain started thinking I have heard of people scraping treadmills for lathes y not beef up up the mini mill found a treadmill on kijiji for free all that was wrong with it was a blown fuse on the motor controller so on to the project I was pleasantly surprised that it had a 2 hp 90 volt DC motor plan on using the belt and pulls of the treadmill just wondering has any one done this anyone done this any help full hints or constructive criticism trying to figure out the mounting aspect of the motor will post some pictures as I get going