- Joined

- Nov 30, 2022

- Messages

- 19

Hello All

Several questions from you more experienced than me. As the title says I am cleaning up and preparing to repaint

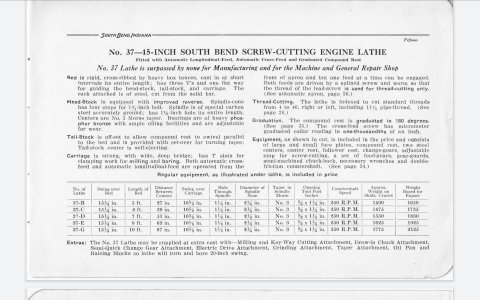

what I believe to be is a greatly abused 15 in South Bend lathe around the 1914 era. Learned to operate this lathe before high school. Have all the pieces, nothing locked up, lathe bed ways scarred up, , definitely not much loving care. Still holds good tolerance.

Have removed the spindle bearing caps, & removed the spindle assembly, and chuck. Anyone have a suggestion or idea as to what the bronze bushing clearence should be, and is there a torque value for the bearing caps. Brass shim stock under the bushings.The bushings and the bearing surface are not the best, but will have to do. I figure the scratches and gouges will just hold that much more lubricant

Where can I purchase the old time brass oil cups with the flip cap. With all the new technology on lubricants what would be the best friction reducing lubricant for the old machine.

Thanks in advance for thoughts, and or suggestions.

Several questions from you more experienced than me. As the title says I am cleaning up and preparing to repaint

what I believe to be is a greatly abused 15 in South Bend lathe around the 1914 era. Learned to operate this lathe before high school. Have all the pieces, nothing locked up, lathe bed ways scarred up, , definitely not much loving care. Still holds good tolerance.

Have removed the spindle bearing caps, & removed the spindle assembly, and chuck. Anyone have a suggestion or idea as to what the bronze bushing clearence should be, and is there a torque value for the bearing caps. Brass shim stock under the bushings.The bushings and the bearing surface are not the best, but will have to do. I figure the scratches and gouges will just hold that much more lubricant

Where can I purchase the old time brass oil cups with the flip cap. With all the new technology on lubricants what would be the best friction reducing lubricant for the old machine.

Thanks in advance for thoughts, and or suggestions.