- Joined

- Jan 23, 2017

- Messages

- 228

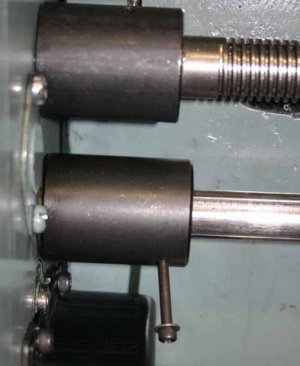

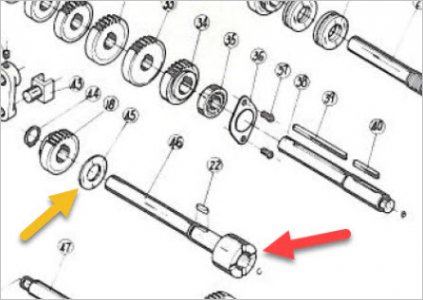

I'm wondering about what's involved removing the power feed rod. There is a vertical bearing block on tailstock end. It has bearings on the RHS for each of 3 rods that terminate there. It kind of appears like I could loosen the bolts that secure block to main way casting & slide it off to the right exposing the rod ends? Then pull the power feed bar through the carriage? Its basically a round rod with a continuous keyway milled in that I guess engages the feed assembly inside the carriage. Or would that be dicey threading the needle back into the carriage again? Anyone come across a teardown /disassembly link for lathes like this?

Make sure the keyway goes all the way through to the headstock end. some lathes are designed to free the feed rod, lead screw, and start selector shaft from their couplings, and remove them with the Apron. Other than that, I'd say you're on the right track.

BTW, that ball clutch is pretty forgiving as far as adjustment, as long as you don't fully lock it up. Sometimes, I think the shear pins were a better idea.