- Joined

- Feb 7, 2019

- Messages

- 64

Hey all

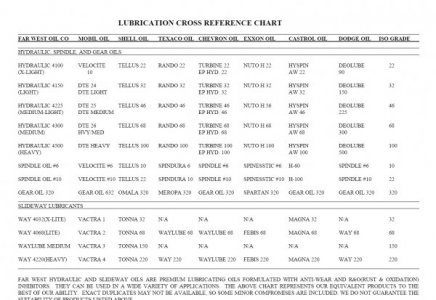

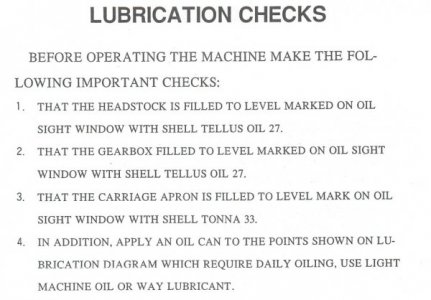

Been looking through past posts from other members regarding lubrication recommendations for my 1440 gear-head lathe. My manual states Chevron AIO #68 in the head stock and gearbox with Chevron AIO #32 in the apron. In both circumstances adjacent to the listed lubrication in parentheses there is a note “hydraulic oil”. After doing my own research I found that the "AIO" is an acronym for "Authentic Industrial Oils"; that really got me nowhere until I found the attached “Eco Lubricants Table of Equivalents”.

I’ve read multiple posts regarding the use on DTE Heavy Medium as an alternative or replacement for the factory installed lubricant however the table states this product is a turbine oil with a much lower Viscosity Index rating at 95 compared to the Mobil hydraulic oil DTE 10 Excel 68 with Viscosity Index rating at 156. See below link for more information on the Viscosity Index

https://www.machinerylubrication.com/Read/28956/lubricant-viscosity-index

The DTE Heavy Medium seems to be more available and in smaller quantities than the DTE 10 Excel however it is available in a 5 gallon bucket and it has a long shelf life. Unlike the DTE Heavy Medium the DTE 10 Excel has no rust inhibitor but with enclosed gears and being splash lubricated is that really a down side?

Wanting to keep with the manufactures recommendation, I see on the table the equal to Mobil DTE 10 Excel 68 would be Chevron Rando HDZ 68. The Chevron product has an index rating of 154 however it does have a rust inhibitor unlike the Mobil DTE 10. Its also available in 5 gallon buckets and its $50 cheaper than Mobil product. Is anyone familiar with this product?

See all attachments

…Comments please

Been looking through past posts from other members regarding lubrication recommendations for my 1440 gear-head lathe. My manual states Chevron AIO #68 in the head stock and gearbox with Chevron AIO #32 in the apron. In both circumstances adjacent to the listed lubrication in parentheses there is a note “hydraulic oil”. After doing my own research I found that the "AIO" is an acronym for "Authentic Industrial Oils"; that really got me nowhere until I found the attached “Eco Lubricants Table of Equivalents”.

I’ve read multiple posts regarding the use on DTE Heavy Medium as an alternative or replacement for the factory installed lubricant however the table states this product is a turbine oil with a much lower Viscosity Index rating at 95 compared to the Mobil hydraulic oil DTE 10 Excel 68 with Viscosity Index rating at 156. See below link for more information on the Viscosity Index

https://www.machinerylubrication.com/Read/28956/lubricant-viscosity-index

The DTE Heavy Medium seems to be more available and in smaller quantities than the DTE 10 Excel however it is available in a 5 gallon bucket and it has a long shelf life. Unlike the DTE Heavy Medium the DTE 10 Excel has no rust inhibitor but with enclosed gears and being splash lubricated is that really a down side?

Wanting to keep with the manufactures recommendation, I see on the table the equal to Mobil DTE 10 Excel 68 would be Chevron Rando HDZ 68. The Chevron product has an index rating of 154 however it does have a rust inhibitor unlike the Mobil DTE 10. Its also available in 5 gallon buckets and its $50 cheaper than Mobil product. Is anyone familiar with this product?

See all attachments

…Comments please