- Joined

- May 7, 2013

- Messages

- 216

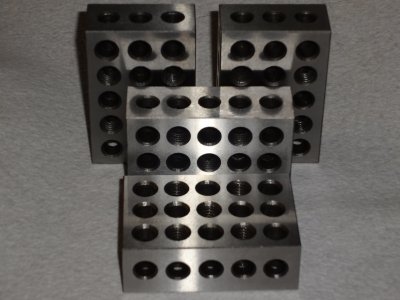

I finished a set for Chucktn and they are harder the well you know what. I've a couple of sets China made the same as the rest and I made a set of cast iron with just 3/8" holes in it. I have yet to have to screw them together for any work of done. Now Chuck wanted them drilled to make an angle plate 90 deg but my personal is an angle plate because them I know it's square and I trust them because I made and ground them when at work with very good machines to check them.

Todd

Oh and carbide end mills tend to chip due to the extreme hardness and interrupted cut.

Todd

Oh and carbide end mills tend to chip due to the extreme hardness and interrupted cut.