-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

[Newbie] 10x18 Lathe Squeaks When Run.

- Thread starter jwest7788

- Start date

B

Bill Gruby

Forum Guest

Register Today

I listened to the video and I agree with the dry bearing.

"Billy G"

"Billy G"

- Joined

- Apr 20, 2015

- Messages

- 50

Hey All,

I also believe the issue was a dry bearing now, little fiddle farting and what not and I have it running smooth.

Quick question about gearbox/headstock oil.

When cold, how thick should it be? It's essentially molasses when I cracked her open cold. Both in consistency, as well as colour. Just wanted to get everyone's take.

Also, My oil level peep is pitch black, and totally opaque, any thoughts?

Thanks All!

I also believe the issue was a dry bearing now, little fiddle farting and what not and I have it running smooth.

Quick question about gearbox/headstock oil.

When cold, how thick should it be? It's essentially molasses when I cracked her open cold. Both in consistency, as well as colour. Just wanted to get everyone's take.

Also, My oil level peep is pitch black, and totally opaque, any thoughts?

Thanks All!

- Joined

- Apr 20, 2015

- Messages

- 50

:/ Maybe the oil is toast, causing the original issue.

It is clear if you smear it, but it's mighty dark. Yesterday when I thought to actually crack her open before running her for the day, at first I thought there was no oil at all, as all the littel bubbles floated to the top, then basically solidified, leaving a "texture" that looked like the thing was empty.

Anyone have a link to the proper way to drain and fill a metal lathe when you cannot use the peep, and the manual is garbage?

It is clear if you smear it, but it's mighty dark. Yesterday when I thought to actually crack her open before running her for the day, at first I thought there was no oil at all, as all the littel bubbles floated to the top, then basically solidified, leaving a "texture" that looked like the thing was empty.

Anyone have a link to the proper way to drain and fill a metal lathe when you cannot use the peep, and the manual is garbage?

- Joined

- Apr 20, 2015

- Messages

- 50

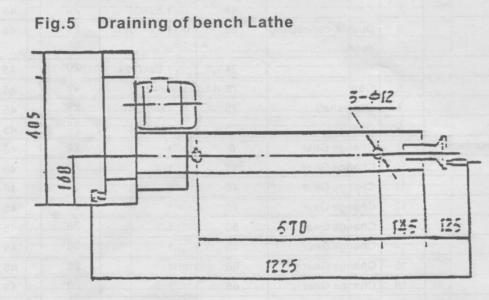

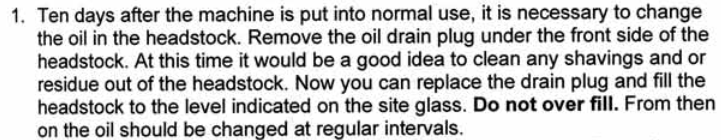

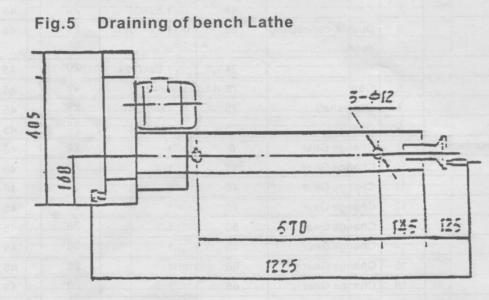

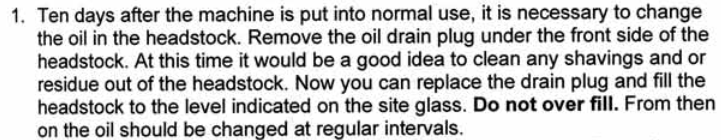

In case anyone is wondering, here's what I've got in my manual for what type of oil, etc: (Drain plug location, and this picture, lol)

So... Run it till warm, Drain it, (Clean it out with something? Brake Clean? Soapy Water?)

Fill it with something non detergent to my best guess based on the opaque site glass?

I'm concerned with how super thick this stuff is, that getting it out is going to be a huge pain in the read. Is there some kind product I can put in the head to help break up the oil? (I'm not sure I can properly convey how thick it is, like full drops solidify to the inside of the lid and never dropped off etc.)

Hah, I'm doomed. Lol

So... Run it till warm, Drain it, (Clean it out with something? Brake Clean? Soapy Water?)

Fill it with something non detergent to my best guess based on the opaque site glass?

I'm concerned with how super thick this stuff is, that getting it out is going to be a huge pain in the read. Is there some kind product I can put in the head to help break up the oil? (I'm not sure I can properly convey how thick it is, like full drops solidify to the inside of the lid and never dropped off etc.)

Hah, I'm doomed. Lol

Seems like mine used 20 or 30 I'll have to look to remember. No need to clean it out if it is still new looking. If someone dumped used oil from there car if consider looking into cleaning it. Just drain it & refill. First take some out in a clear container to see if it is as bad as you think. Oil should stick to the flat top in drops,

- Joined

- Nov 9, 2013

- Messages

- 790

You can also check your side gears to make sure they are not adjusted too tightly. There needs to be slight backlash so the gear teeth are not "fully" engaged. This can make them loud, and also make them wear out prematurely. Side gear lube can also help. I use Royal Purple 90w-140 full synthetic differential lube. It is sticky, and makes the gears run smooth and quiet.

Many Enco / Grizzly / and other Asian gear head lathes specify ISO-32 or ISO-64 hydraulic oil. Basically 10 weight or 20 weight hydraulic oil. As others have mentioned, it should not be dark or thick. Sounds like someone may have used the wrong lube. This could also cause excessive internal loading and gear noise.

GG

Many Enco / Grizzly / and other Asian gear head lathes specify ISO-32 or ISO-64 hydraulic oil. Basically 10 weight or 20 weight hydraulic oil. As others have mentioned, it should not be dark or thick. Sounds like someone may have used the wrong lube. This could also cause excessive internal loading and gear noise.

GG

- Joined

- Apr 20, 2015

- Messages

- 50

Hey All,

So, Thought I had this solved, but yesterday while warming up the squeak of doom has returned!

Additionally, when i went to use high speeds, it did not sound good at all, like, clearly something not good going on, so I immediately turned her off and called that the end of the day until I get some new oil in her.

How much oil should I buy?

Anyone have objections with me using this? (32)

http://www.princessauto.com/en/detail/aw-32-hydraulic-oil/A-p8479081e

Or a 36?

http://www.princessauto.com/en/detail/all-season-36-hydraulic-oil/A-p8479164e

64?

http://www.princessauto.com/en/detail/all-season-68-hydraulic-oil/A-p8479222e

For flushing purposes, any risk in draining what I can, Filling with new stuff, Run the machine, drain, and fill with new stuff again? (Risk in mixing too much of the old and new?)

Or how do I clean out the mess of old oil? (It's too thick, I'm confident, haha)

Edit: Checked the change gears, and belts. Noise definitely coming from the front of the head stock, pretty confident it's that main bearing not getting lubed, as the oil is too thick to flow through the little oil way.

Thanks all!

So, Thought I had this solved, but yesterday while warming up the squeak of doom has returned!

Additionally, when i went to use high speeds, it did not sound good at all, like, clearly something not good going on, so I immediately turned her off and called that the end of the day until I get some new oil in her.

How much oil should I buy?

Anyone have objections with me using this? (32)

http://www.princessauto.com/en/detail/aw-32-hydraulic-oil/A-p8479081e

Or a 36?

http://www.princessauto.com/en/detail/all-season-36-hydraulic-oil/A-p8479164e

64?

http://www.princessauto.com/en/detail/all-season-68-hydraulic-oil/A-p8479222e

For flushing purposes, any risk in draining what I can, Filling with new stuff, Run the machine, drain, and fill with new stuff again? (Risk in mixing too much of the old and new?)

Or how do I clean out the mess of old oil? (It's too thick, I'm confident, haha)

Edit: Checked the change gears, and belts. Noise definitely coming from the front of the head stock, pretty confident it's that main bearing not getting lubed, as the oil is too thick to flow through the little oil way.

Thanks all!

Last edited: