- Joined

- Oct 14, 2014

- Messages

- 1,970

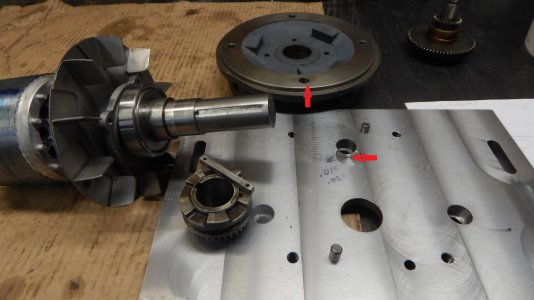

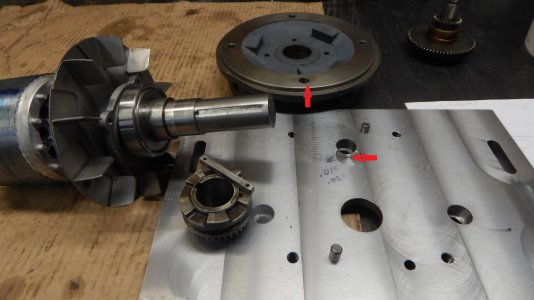

Turned the motor shaft down to 1.25 and keyed it. Got the sliding backgear shift (beside motor shaft) working nice.

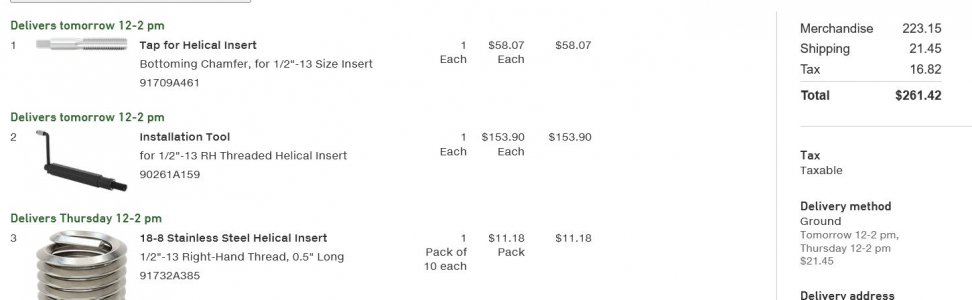

Now, at least for me, every job has at least one fark up. The marked hole for the motor was off 15 thou and I did not oversize the bolt bore - dumb. On first install, I stripped the threads on the motor. Got to heli coil this one before motor assembly. Then manufactue motor mounts and put it all together

Now, at least for me, every job has at least one fark up. The marked hole for the motor was off 15 thou and I did not oversize the bolt bore - dumb. On first install, I stripped the threads on the motor. Got to heli coil this one before motor assembly. Then manufactue motor mounts and put it all together