- Joined

- Mar 24, 2016

- Messages

- 100

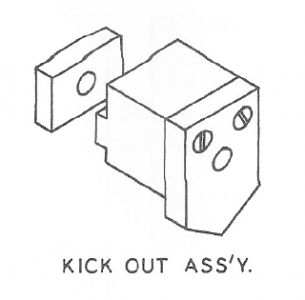

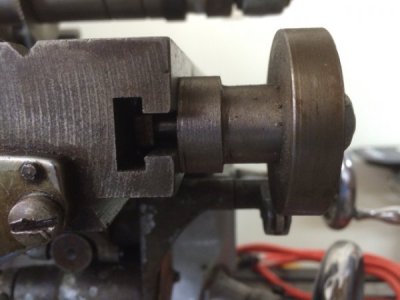

wa5cab, in the picture Steve showed of his mill with the round substitute standard kick out cam in place, it was located at the left end of the table. BUTTT... the nut on the front is to hold it in place and there is a T-nut in the front slot to hold that part in place. You can loosen it and slide the cam to any position on the slot so the cam may be located to turn the feed off whenever desired. Mine has a nut that is loosened (see picture included.)