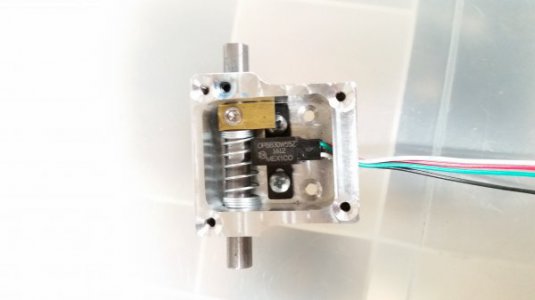

Gents - adding another to the growing collection of conversions. I did not go the standard HOSS conversion or pre-made conversion route. I did however, buy my ballscrews with double nuts precut direct from Chai (linearmotionbearings2008), and bought all the controller components from Automation Technologies. After some hiccups getting the controller box laid out and wired to my liking I ran into some more issues with stepper timing. Apparently timing on the X/Y steppers needed to be divided by 5, I have no idea why this is. One thing to note is the 9082 stepper driver is substantially bigger than the 5056 and mounts had to be made to fit it in the enclosure.

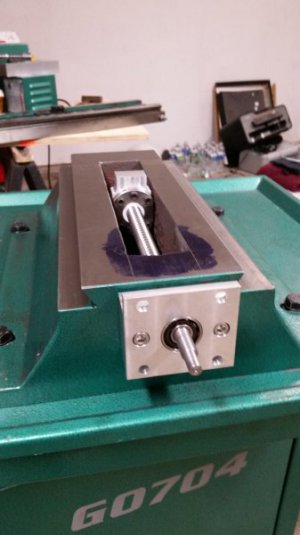

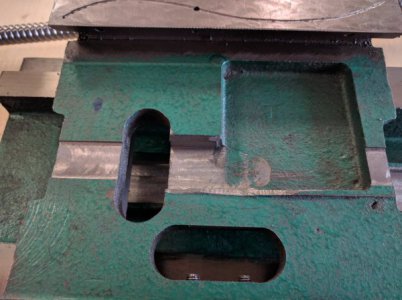

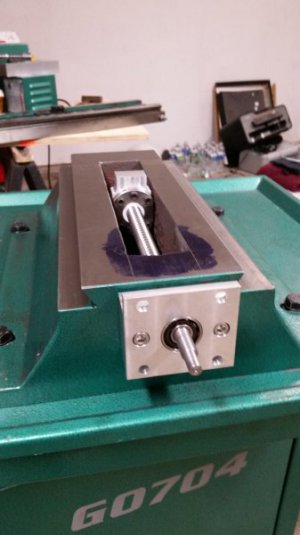

From a hardware standpoint, everything went as usual except the x-axis ballmount. In addition to cutting clearances on the x ballnut, I had to grind out the bottom of the table to clear. I am bringing it, as well as the saddle to a friends to have it machined properly this weekend. As it stands I did not grind it close enough to the ends and the x-axis bound up if panned over too far. I also plan on redoing my stepper mounts and angular contact bearing setups. On the advice of a coworker, I am going to back the bearings up to each other and preload them against each other, then capture the whole assembly.

I also predrilled all the holes and cut the grooves necessary for a one shot oil system. I've been fiddling with some custom low profile banjo fittings but they've become more trouble than they're worth and I might go back to off the shelf fitings.

Here are the current specs and some pictures. I would take some more pics of it completed but it's taken apart to be machined this weekend.

X Axis: 570 oz-in Nema 23, 1605 ballscrew with double nuts, Keling 5056D 5.6A driver

Y Axis: 570 oz-in Nema 23, 1605 ballscrew with double nuts, Keling 5056D 5.6A driver

Z Axis: 906 oz-in Nema 34, 2005 ballscrew with double nuts, Keling 9082D 8.2A driver

I'm using a 48V 12.5A Keling PSU and KL-DB25 breakout board. I built a desktop to run LinuxCNC.

Side note, what's the best way to add videos? I have a couple of it running. Should I upload to YouTube?

From a hardware standpoint, everything went as usual except the x-axis ballmount. In addition to cutting clearances on the x ballnut, I had to grind out the bottom of the table to clear. I am bringing it, as well as the saddle to a friends to have it machined properly this weekend. As it stands I did not grind it close enough to the ends and the x-axis bound up if panned over too far. I also plan on redoing my stepper mounts and angular contact bearing setups. On the advice of a coworker, I am going to back the bearings up to each other and preload them against each other, then capture the whole assembly.

I also predrilled all the holes and cut the grooves necessary for a one shot oil system. I've been fiddling with some custom low profile banjo fittings but they've become more trouble than they're worth and I might go back to off the shelf fitings.

Here are the current specs and some pictures. I would take some more pics of it completed but it's taken apart to be machined this weekend.

X Axis: 570 oz-in Nema 23, 1605 ballscrew with double nuts, Keling 5056D 5.6A driver

Y Axis: 570 oz-in Nema 23, 1605 ballscrew with double nuts, Keling 5056D 5.6A driver

Z Axis: 906 oz-in Nema 34, 2005 ballscrew with double nuts, Keling 9082D 8.2A driver

I'm using a 48V 12.5A Keling PSU and KL-DB25 breakout board. I built a desktop to run LinuxCNC.

Side note, what's the best way to add videos? I have a couple of it running. Should I upload to YouTube?