- Joined

- Mar 7, 2017

- Messages

- 8

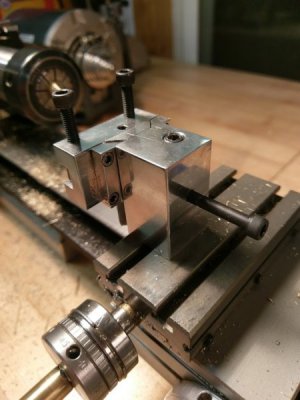

Casey, if your milling vise is accurate and the milling attachment is 90 degrees and square to the bed of the lathe then you should be able to get most of the work square without parallels. I assume/hope you have checked the vise and milling attachment for accuracy, right?

If you want to mill stuff, you need parallels. The cheap short 3" ones linked to at LMS will not break the bank and are worth buying. I use HSS tool bits as parallels on occasion but for thin work, like your dovetail part, you need something that positions the part at the right height; I suggest you buy the parallel set and get on with it. (I use that set on my Sherline mill and they are fine for a Taig/Sherline-sized vise.)

Has it dawned on you that you need a milling machine yet?

I have check the accuracy, and its pretty well dead on, as far as I can measure. Its the part that I'm not getting mounted in the vice in both x and y. I went ahead and have ordered the LMS set. And yeah, I've been needing (wanting) a milling machine for a while now, but, for me, the first step is getting a house that I own so I can have a workshop to myself.