I just

have to jump in here. If electricians really earn that much money out there, maybe I need to come out of retirement (spitting at 70) if they would have me. I'll work for somewhat less. All for a standard three wire control station yet.

A power hacksaw, assuming something for casual use, is going to be one HP or smaller. A fractional HP motor

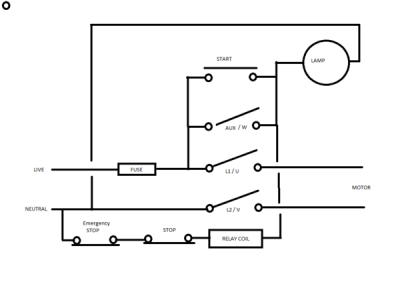

can be run on a large relay. A NEMA Size 00 starter would be best, but that can get real expensive real fast. BritSteel above has a good schematic, but there are some things I would do different in the States. First off, you must

never switch the neutral. The NEC does not allow it here. A good way to get knocked on your butt, or worse........ I am going to talk at the grammar school level because you are talking of calling in a "pro" who will make it sound really difficult. It isn't

to me. But for someone that doesn't know, well........

As an exercise, find a small relay. Find a 120 volt relay if you can. A "KHU17A11-120" is much too small for

any motor. Will drive the light, though. The power plug, US standard, will have a wide slot, a narrow slot, and a round(ish) hole. The wide slot is the neutral, at ground potential.(theoreticly) The narrow slot is the "hot" lead and will sit you on your butt if you touch it. Even dry.....

Looking at the switch, the black button is start. Find the two connections for a "normally open" contact. The red button is "stop" and you will find a set of terminals for a "normally closed" contact. It looks like a very old Allen-Bradley switch, a nice one it is too. Very clean as well. In a steel mill parts system, they don't look that good even when they're new. The dust gets inside the boxes.

Run a wire from the line side of a plug, the narrow finger, to the stop switch. Another wire from the other side of the stop switch to one side of the start switch. Later, there will be a second wire here. From the other side of the start switch, a wire to one side of the coil of the relay. The other side of the relay then connects to neutral, the wide finger of the plug. When this is powered up, the relay should come on as long as you hold down the start switch. Remember to unplug it at this point.

Now, on the relay find a pair of contacts that are normally open when the relay is off. One of those will connect to the line side of the coil, where the push buttons are connected. The other side of that contact will connect to the short wire between the stop and start switch. The place I had said another wire would connect later. When you plug it in this time, pressing and releasing the start button should cause the relay to pick up and stay on, until you press the stop button. If it chatters, you got the buttons crossed up. No biggie. If you got the wire from the contact to the wrong terminal, it'll just blow the fuse. Lots of "spitzenpoppen und crackenpoppen". Again, no biggie........

If all you can find are 12 or 24 volt relays, it will still work. Just get a doorbell transformer to do the hook-up. The motor will likely be 120 volts, possibly 240 volts. Try to match the relay to the motor if you can. It isn't vital, but makes things a lot easier. Again, the best bet is a NEMA Size 00 contactor. The used price may make you change your mind about a simple ON-OFF switch.

Depending on where and when the machine was used, it

may have a low voltage control system. If that is the case, the lamp will explode on 120 volts. Best just leave it off for now. I would highly recommend 16 AWG THHN wire for the hook-ups. It is available at any home center, hopefully in short pieces. And that gets into conduit and some other subjects. I am going to include a link, although it doesn't cover such basic wiring as this. Look just below "Stuff worth looking at" for "Home Shop Electrics".

http://www.hudsontelcom.com/ Reading this may give a little insight into the subject. Feel free to contact me if this really is where you want to go.

Bill Hudson