Hi IHinIN.. That's exciting! I would be surprised if there were box ways on any axis on a BP clone, but anything is possible.. Most BP clones have dovetail ways on all axis.. I do see that the

column itself is box shaped. **edit** found a used one online (looks like Ohio actually) and the Model 1050 looks like it has dovetail ways on all axis.

Cool that they already Turcite-d the ways.. sounds like it will work nicely. I would check to see if there is lube, and the central lube works properly (which this probably has a central lube).. Turcite degrades somewhat-more-readily than bare cast iron if chips and swarf were allowed to stay on the machine indefinitely. Just move the axis ALL THE WAY each direction, end to end to check for wear.

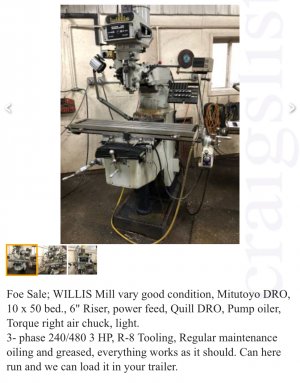

Looks like this thing weighs 2800 lbs, so quite a bit heavier than an actual BP, which might be because of a larger square column?

I had not heard of that importer until your post, but don't keep up on these things.. Their website looks pretty serious, and my take is a good sign that the company makes CNC and other machines for companies now- meaning they don't specialize in "hobby" machines. Not that some companies that focus on hobbyist sales aren't awesome, but some companies aren't.

Any idea what model the Willis mill is? They all look pretty serious. If you are correct about the table dimensions, it looks they call it a 1050 model. At least 3hp or 5hp, R8 or 40 spindle..

Do you already know about milling machines etc? This looks like a very capable machine for most people, especially hobbyists, according to the specs!

There is a video by the manufacturer on YouTube about the machine:

Willis 1050 Knee Mill Intro

Bernie