-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Why Am I Unable To Plunge Cut A Bronze Casting

- Thread starter tomw

- Start date

- Joined

- Jan 24, 2015

- Messages

- 239

I heard from Jim at PM research. This is what he says:

Interesting, and impossible for me without buying yet another attachment for the Sherline (the high-speed spindle pulley). I can get close to 3K spindle speed now, but not twice that fast.

Here is some information on the bronze 937 alloy: http://www.anchorbronze.com/c93700.htm, and the Wikipedia page on copper alloys: https://en.wikipedia.org/wiki/List_of_copper_alloys.

Hmmm.

Tom

It is the same Bronze used for the 3 and 7 cylinders. It is bronze ingot 305 part # 937 Bronze. Paul recommends that you mill it out with a ¼ end mill first at speeds of 1500-3000 rpm and when you get to the smaller end mills, the speeds should be 3000 – 6000 rpms.

Interesting, and impossible for me without buying yet another attachment for the Sherline (the high-speed spindle pulley). I can get close to 3K spindle speed now, but not twice that fast.

Here is some information on the bronze 937 alloy: http://www.anchorbronze.com/c93700.htm, and the Wikipedia page on copper alloys: https://en.wikipedia.org/wiki/List_of_copper_alloys.

Hmmm.

Tom

- Joined

- Sep 5, 2013

- Messages

- 3,789

I heard from Jim at PM research. This is what he says:

Interesting, and impossible for me without buying yet another attachment for the Sherline (the high-speed spindle pulley). I can get close to 3K spindle speed now, but not twice that fast.

Here is some information on the bronze 937 alloy: http://www.anchorbronze.com/c93700.htm, and the Wikipedia page on copper alloys: https://en.wikipedia.org/wiki/List_of_copper_alloys.

Tom

Well that's just weird. With the high lead content in there I would have thought it'd cut like a dream.

-frank

- Joined

- Mar 19, 2014

- Messages

- 2,682

Ingot 305 has a machinability rating of 70%, even with the lead in it? But, still not a problem to machine, even with HSS. And I would not be overly concerned about not being able to get the mentioned high spindle speed. I think your achillis heel is your Sherline mill, sorry. I think you will need to learn its idiosyncrasies for achieving proper machining results. This is where I think a good background in making chips on a conventional machine can be very helpful. Then, when you step in front of a Sherline, Unimat or the like you will have the background knowledge to overcome the pitfalls of said machines…Dave

Last edited:

- Joined

- Jan 24, 2015

- Messages

- 239

Update:

I received my 1/8" carbide end mills. They are 3/8" shanks, 1/8" diameter cutter, 3/8" depth.

I didn't notice the last bit.

Anyway, milling with the carbide end mills at 2800 rpm cut this stuff like butter! The cuts were smooth in feel and produced a nice smooth surface. Unfortunately, the cutter depth (length of the 1/8" dia tip) was not enough to mill all the way to the edges of the pocket. Since side milling with my HSS bits didn't seem completely terrible (terrible, but not completely), I finished off the pocket with a hopefully sharp 1/8 2 flute HSS end mill that had a long enough cutting tip.

I then milled the steam ports with a 1/16" carbide mill I already had.

Below is a photo showing the result of my milling. The crappy surface along the margins is from the HSS bit. The smoother center is from the carbide bit. The screwed up edges are from my previous efforts.

It looks really ugly in the photo, but after a bit of sanding with 400 on a flat tipped sanding bar (a bit of dimensionally sound brass about the right width) things looked not bad. The margins are still all effed up, but the critical central section that was milled with the carbide bit looks great. Unfortunately, no photo. I will try to remember to post one later.

Also, the valve ports look great! Kind of...

BTW, anyone know of a source for 1/8" carbide bits with a cutting depth greater than 3/8"? If I had that, it all would have looked great!

Thank you so much for your help.

Cheers,

Tom

I received my 1/8" carbide end mills. They are 3/8" shanks, 1/8" diameter cutter, 3/8" depth.

I didn't notice the last bit.

Anyway, milling with the carbide end mills at 2800 rpm cut this stuff like butter! The cuts were smooth in feel and produced a nice smooth surface. Unfortunately, the cutter depth (length of the 1/8" dia tip) was not enough to mill all the way to the edges of the pocket. Since side milling with my HSS bits didn't seem completely terrible (terrible, but not completely), I finished off the pocket with a hopefully sharp 1/8 2 flute HSS end mill that had a long enough cutting tip.

I then milled the steam ports with a 1/16" carbide mill I already had.

Below is a photo showing the result of my milling. The crappy surface along the margins is from the HSS bit. The smoother center is from the carbide bit. The screwed up edges are from my previous efforts.

It looks really ugly in the photo, but after a bit of sanding with 400 on a flat tipped sanding bar (a bit of dimensionally sound brass about the right width) things looked not bad. The margins are still all effed up, but the critical central section that was milled with the carbide bit looks great. Unfortunately, no photo. I will try to remember to post one later.

Also, the valve ports look great! Kind of...

BTW, anyone know of a source for 1/8" carbide bits with a cutting depth greater than 3/8"? If I had that, it all would have looked great!

Thank you so much for your help.

Cheers,

Tom

- Joined

- Dec 6, 2015

- Messages

- 8

Hope this link works

http://www.travers.com/2-4-flute-lo...grain-solid-carbide-single-end-mills/p/38546/

Art

http://www.travers.com/2-4-flute-lo...grain-solid-carbide-single-end-mills/p/38546/

Art

- Joined

- Dec 3, 2015

- Messages

- 243

My approach would be to drill holes of the appropriate size in each corner, to the proper depth. Then using choice of proper sized end mills, go to any of the holes starting location. touch off the top of the part, lower cutter .05 in depth and traverse left to right or front to back depending on your preference, using a helical pattern, following the outside contour, remove all material within the pocket. Repeat as necessary until you reach your proper depth.

The holes in the corners simply allow a spot for you to take a break. For best results, leave .015 on the outside wall for a finish pass that you cut using the climb milling direction and at a higher RPM but same feed rate. This will give you a very nice finish.

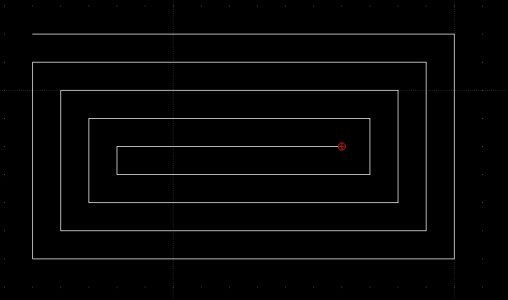

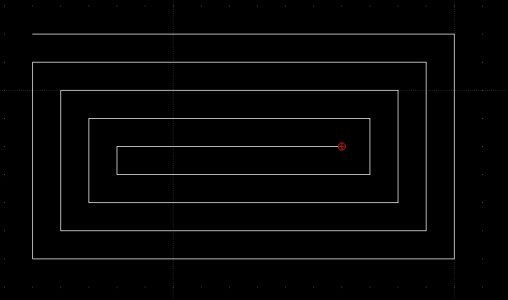

This is the pattern I was referring to, I did not put the holes in the corner so it would be more clear.

The holes in the corners simply allow a spot for you to take a break. For best results, leave .015 on the outside wall for a finish pass that you cut using the climb milling direction and at a higher RPM but same feed rate. This will give you a very nice finish.

This is the pattern I was referring to, I did not put the holes in the corner so it would be more clear.

Last edited:

Dear All,

I am working on a bronze cylinder casting from PM Research. I am trying to get the steam chest milled, which requires that I make plunge cuts. I have tried 2 and 4 flute center cutting mills, but they do NOT plunge! They just sort of buff the surface. I have done lots of plunge cutting in aluminum, CI, and brass. What the hell am I doing wrong.

I have tried 4 different end mills in two different sizes. All center cutting.

Any help will be much appreciated. This seems like an easy part to work on!

Cheers,

Tom

Tom,

An End mill is for milling at the end but not for plunge cutting. A slot drill is for plunge cutting, but be aware that as the cutting faces have one overlapping the centre of the tool it will tend to cut slightly larger than its own diameter. To counter this tendency use a smaller slot drill and then finish with a slot drill or an end mill of the chosen size. The hole will still be slightly over but less so. If the hole needs to be very accurate to then finish with a reamer.

Generally most Bronze is not had to cut. It is said that some grades of Aluminum Bronze are harder, but in most cases you will not have a problem, unless the casting has been poured to hot and you have "burn on", that is when the mould sand tends to burn into the surface of the metal. The sand of course is very abrasive.

OK,

LOL Against all odds, here is my opinion.

If it is gummy and grabbing here is my experience. I machine C110 Copper on a daily basis. It is EXTREMLY gummy and grabs tooling.

Drilling with a .125 bit into the face, BTW I make X-Fire bullets. At 5,000 RPM with a feed rate .0025 I was shearing bits every 5-25 drills. I bumped the RPM to 6,000 and dropped the FR to .0020. I have gotten over 1,000 drills to this current bit which is a high speed steel. When running gummy material, if you wish to damage your tooling by all means go slow. I turn the C110 at 5.000 RPM with a 55 degree tooling. Larger drill bits I turn at 5,000 RPM, Smaller are 6,000 with slower feed rates.

Nick

LOL Against all odds, here is my opinion.

If it is gummy and grabbing here is my experience. I machine C110 Copper on a daily basis. It is EXTREMLY gummy and grabs tooling.

Drilling with a .125 bit into the face, BTW I make X-Fire bullets. At 5,000 RPM with a feed rate .0025 I was shearing bits every 5-25 drills. I bumped the RPM to 6,000 and dropped the FR to .0020. I have gotten over 1,000 drills to this current bit which is a high speed steel. When running gummy material, if you wish to damage your tooling by all means go slow. I turn the C110 at 5.000 RPM with a 55 degree tooling. Larger drill bits I turn at 5,000 RPM, Smaller are 6,000 with slower feed rates.

Nick