- Joined

- Mar 26, 2018

- Messages

- 2,725

I would personally turn up my nose at the 1.8kW DMM motor. A speed increase through pulleys is possible but always more difficult than speed reduction. You would not be able to run that motor on a VFD as you would need to pull the commutation data out of their 17-bit serial encoder (likely impossible). When you go above the rated speed, the motor torque will drop off a bit so you likely wouldn't have the torque you would hope for at higher speeds.

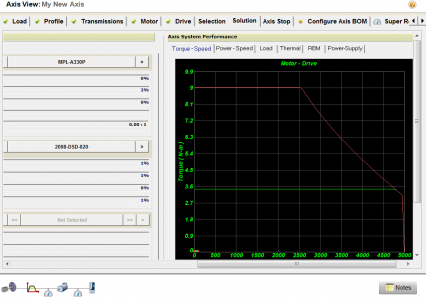

My setup is the best I have been able to come up with so far. 1:1 gearing of an Allen Bradley MPL-A330P-xxxxxx servo and an Ultra 3000 (2098-DSD-020x-xx) drive. The "xx" are characters which don't affect the performance of the motor. That is 1.8kW but a rated/maximum speed of 5000rpm. With a 1:1.5 gearing you could easily get 7500 rpm. These are available on ebay and I could help you set it up.

Think hard about if you really need a servo. They are great, very compact, and very powerful, but also very expensive. A 3600rpm inverter duty induction motor could be set up to run at 7200rpm within reason. You wouldn't get the stability in speed that a servo gives you, or any kind of rigid tapping/spindle positioning, but you could save some $$.

I would say that DMM is a great choice for the axis motors.

All of this is just my personal opinion/experience.

My setup is the best I have been able to come up with so far. 1:1 gearing of an Allen Bradley MPL-A330P-xxxxxx servo and an Ultra 3000 (2098-DSD-020x-xx) drive. The "xx" are characters which don't affect the performance of the motor. That is 1.8kW but a rated/maximum speed of 5000rpm. With a 1:1.5 gearing you could easily get 7500 rpm. These are available on ebay and I could help you set it up.

Think hard about if you really need a servo. They are great, very compact, and very powerful, but also very expensive. A 3600rpm inverter duty induction motor could be set up to run at 7200rpm within reason. You wouldn't get the stability in speed that a servo gives you, or any kind of rigid tapping/spindle positioning, but you could save some $$.

I would say that DMM is a great choice for the axis motors.

All of this is just my personal opinion/experience.