I think a very important skill for newbies to learn is something my own skill set is lacking in.

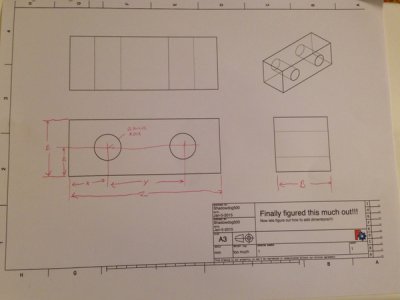

Proper drawings of a part.

Most newbies will just "wing it" when it comes to a project. While this works just fine on a lot of things, there's a chance that someone else may want to make one for themselves! Knowing how to read, and how to make, drawings is important. Quality isn't important at first, just the ability to convey the idea and measurements so the part can be made by others.

Case in point - my vertical spindle for my horizontal mill. I have a few sketches, fewer dimensions, and some things I decided on "off the cuff", with no documentation of dimensions, sizes, etc. I'm fairly well "winging it", and thankfully most dimensions aren't critical. The mounting plate was the correct thickness when it cleaned up, and the final dimensions of the outside of the spindle housing will be whenever fly cutting leaves a nice surface.

Just my 2 cents.

ondering

ondering