Hi I need to braze a small cast iron part that cracked when it was dropped. The piece that broke off is about 1"x.5x.25. I was wondering which method would give the best results. I could mig with bronze wire. Torch it with bronze rod or torch with silver wire.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

What type of brazing rod is best for repairing cast iron

- Thread starter Ebel440

- Start date

- Joined

- Mar 25, 2013

- Messages

- 5,131

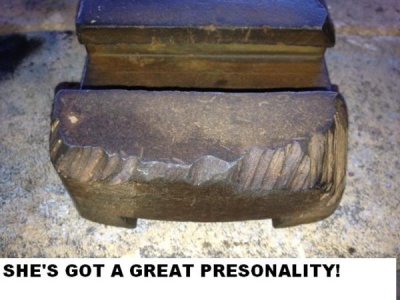

You will get a lot of varied opinions. I just did this and used a flux coated bronze rod with a small OA torch. It worked great. Very strong repair. The joint is visible due to the different color of the metal. I would use this method again.

Reattached the tab on the right.

Robert

Reattached the tab on the right.

Robert

- Joined

- Mar 25, 2013

- Messages

- 5,131

I preheated with a propane torch mainly because I was afraid of cracking the delicate piece with uneven heat. I do not think this was absolutely necessary. You just need enough heat to melt the braze metal. In my case it was a bright red but not orange.

R

R

- Joined

- Mar 3, 2017

- Messages

- 804

I should have mentioned I have no experience brazing cast iron. I have done some steel brazing. ... Did you do any preheat or post heat?

I've been told that preheat is essential, that the cast iron is weak and brittle otherwise.

The idea, is to get it up to a few hundred degrees (not red, just melting-solder),

then it's less brittle. Also, you want it to cool slowly. A bed of cold ashes was

traditional for lowering stress during cooling, modern practice uses ceramic

or maybe fiberglass blankets.

Like, this video:<

Last edited:

- Joined

- Feb 2, 2013

- Messages

- 3,960

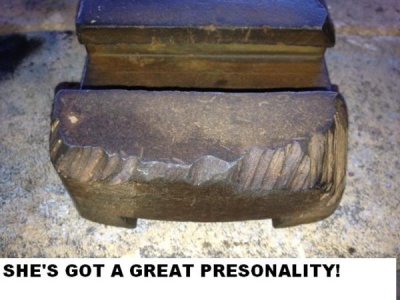

here is a cast iron brazing repair i did on my SB11 lathe compound

before:

After:

you can see the process here:

http://www.hobby-machinist.com/thre...111b-105014-iqr-rebuild-by-ulma-doctor.14399/

before:

After:

you can see the process here:

http://www.hobby-machinist.com/thre...111b-105014-iqr-rebuild-by-ulma-doctor.14399/

Last edited:

- Joined

- Jun 7, 2013

- Messages

- 10,450

I prefer to braze cast iron with oxy/acet. torch. I have done lots of it over the years; for simple small parts, preheat beyond what the torch does is not much necessary. I first grind a vee on the broken halves, on both sides if possible, leaving a unground land to align the parts with respect to each other; then I coat the ground surfaces with silver solder flux to protect them from oxidation when heating and brazing. I use ordinary brazing rod such as welding supply business sell; now the most important part --- most all brazing fluxes, even those purporting to be good on cast iron, are not so good at all; I use Anti Borax EZ #3, it is superior to all others. Also, take care not to overheat the base metal so that it turns black; if it does, the braze will not adhere well. If it does happen, stop, let cool and regrind to bright metal, re flux and start over. The right heat is when the braze metal wets out on the base metal, like regular solder does.

Well I brazed it. I filed the surface down a tiny amount to just get a few thousandths and a few slightly deeper v-groves to hopefully feed the joint. It was the whitest iron I've seen and so hard the file would barely cut. I used a silver braze just because that's what I have more experience with. I brought it up to temperature gradually on a piece of steel and tried to bring it down slowly by heating the plate and then leaving it in a closed grill to cool for a few hours. The joint seems good and nothing else cracked so I guess it worked. Thanks.

- Joined

- Jun 7, 2013

- Messages

- 10,450

Cast iron becomes white and hard like that from the wrong formulation being used for the nature of the casting being poured; you can't use a formulation for light castings on heavy castings or vice versa; one wonders, if it is that hard, how did they machine it? Iron when chilled gets literally glass hard. Malleable iron castings are made from white iron and later annealed. There was much malleable iron used in the old days, but seldom seen any more, having been replaced by ductile iron, which does not need to be annealed to exhibit ductility; in its 60,000 psi alloy, it can be bent like steel. I used it in its 100,000 psi formulation for steam launch crankshafts that I made years ago. Google "York steam launch engine", you will likely find it; it had cylinders 3" & 5 1/4 X 3 3/4" stroke and made about 10 horsepower.