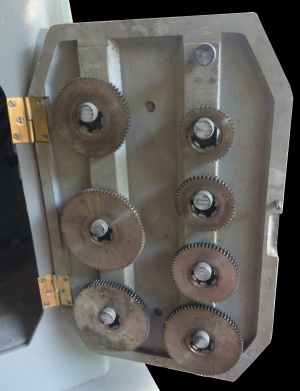

Yours is 100 times the features of mine. Mine was from an old line shaft unit, converted to electric. Just a small drive gear turning the large gear, which drives the ram. No oil pump, no tilting table. About the only bragging rights I have, is the variable speed drive added when the motor was added.But maybe all shapers have the same equipment and this is just par for the course.

You have a great machine.