Wow, thank you all for the responses! Very helpful.

@davidpbest what an amazing list! Even embedded links! The facemill write-up is also really helpful.

I wish I had an unlimited budget, but that is far from the case. So I need to be patient and smart in how I go about this.

Here are my takeaways from your responses:

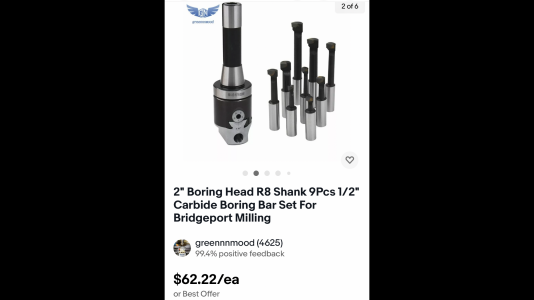

- No need for a boring head right now.

- Since there is no agreement about the vice, the glass is half-full, meaning no wrong answer. I'm not keen on dropping a lot of money on a vice before I know what I'm doing. I'm going to buy the better quality 5" vice from PM. When the day comes that I outgrow it, I'll get something better.

- I had not even thought about squares, dial indicators, etc for setup. Sigh... so I need to buy these.

- Sounds like a facemill will be needed sooner than later.

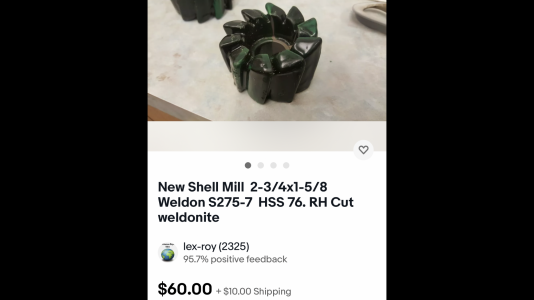

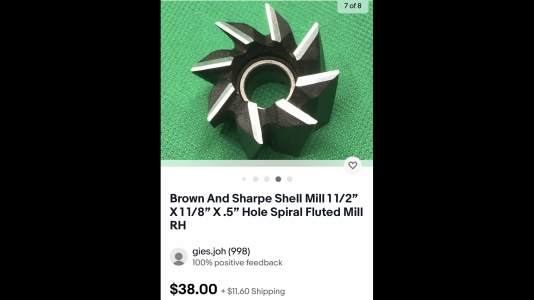

- I like the suggestion to buy a lot of used end mills. I'll watch ebay and craigslist. Might be a bit of a pig in poke, but a good way to get a variety to start with at a lower price.

- Yes I'd love a metal lathe, but the piggy bank will have to be refilled for that to happen.

Yeah, this is something I'll need to grow into over time. Like I had said, I'm hoping to go to PM, and would like to get what makes sense from them in one trip.

After reading the post from

@Bi11Hudson I thought maybe sharing some more background would be good. I'm 60, so gray hair and life experience. Was raised working on cars, houses etc. I know how things work, and pride myself on being able to fix just about anything that is fixable. (I think these traits are dying out BTW) It's rare that I pay anyone to do anything for me, but my 60 year old body has convinced me to stop doing the painfully physical jobs. I've had more than one project at a time going on since I was a kid. I have a pretty decent workshop, but it's mostly woodworking equipment. Yes, I have shaped metal on my old Shopsmith with a file.

When I had my "turning 40 crisis" I bought a motorcycle and a gyroplane. Restored the gyroplane with help of a talented older friend who had a machine shop and could make his Bridgeport mill sing. Sold it before ever flying it because a couple people I became acquainted with on a gyroplane forum crashed and died. My children were still young enough that the risk started to seem irresponsible. Sold the motorcycle several years later, and regretted that. Anyway, the good Lord gave me common sense and I have a healthy respect for things that can kill you. I did take some fixed wing flying lessons, gyroplane flying lessons, have gone up in a small helicopter, a powered parachute, and tried hang gliding in my youth. If there was ever a frustrated pilot wanna be, it's me. Right now I'm working on a 1979 Triumph Spitfire I bought. I didn't say restoring because I'm trying to see if I can shoehorn a Mazda V6 into it. I have a Ford T9 transmission cleaned and disassembled in my workshop. Making the transmission fit properly will take some machining. One of many items to get the engine to fit will be making a custom aluminum part for a remote oil filter. I've drawn the part up in SolidWorks, and my son-in-law has a 3D printer and has started fooling with sand casting, but even if successfully cast, the part would still need finish machining. I'm sure there will be at least a half dozen other parts I'll end up needing to make. If you google "gene weber 1979 triumph spitfire blog" you will find my blog on the project. Good reading if you're trying to cure insomnia.

Anyway, I could go out and have parts machined for me. But as I tell everyone who thinks I should get the Spitfire done ASAP and drive it, It's the doing that is the fun.

Thanks again!