Finally! The Data We've All Been Waiting For...

I screwed with the compressor all day in a fit of obsession, finally got what I wanted out of it. In what follows, there are some "screenshots" (cameraphone pictures of my laptop screen) of the scope graph spit out by the VFD software. The green Horsepower trace is very noisy because of the reciprocating nature of the compressor compounded by periodic sampling rate. It looks like crap but you can get the general idea. Also occasionally one or more values drop to zero; that's a bad connection of my USB>serial converter or a brain fart of the virtual machine I'm running, not sure which, but it doesn't mean the drive stopped; it ran flawlessly.

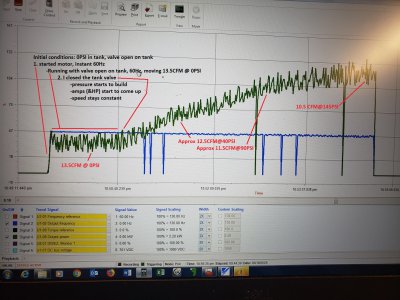

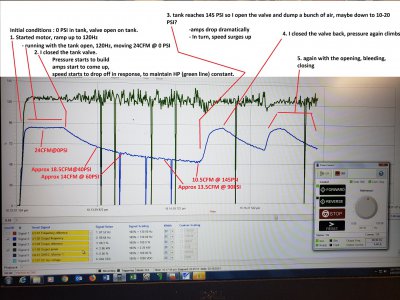

Here's what the HP looks like over a tank charge-up from 0 to 145 PSI

with the motor running at a fixed 60Hz, as it would connected directly to mains power with no VFD. Green line is HP output, blue line is Hz (speed).

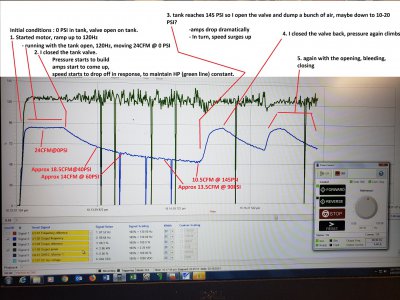

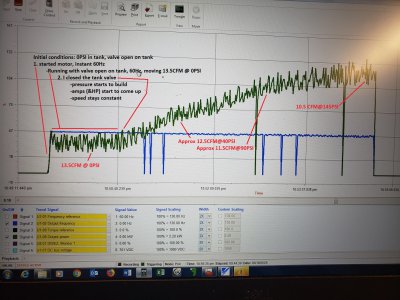

Here's what it looks like in constant horsepower mode. Again, Green line is HP output, blue line is Hz (speed).

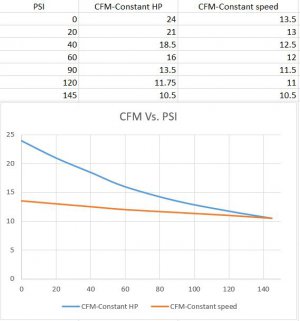

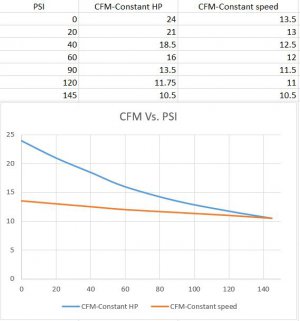

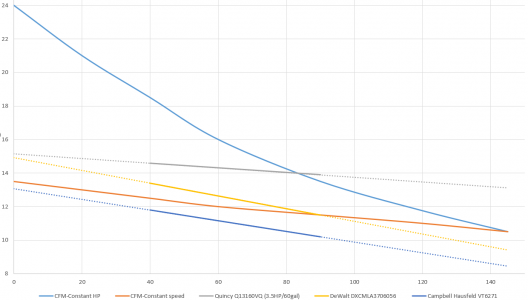

Here is the actual data (no "approx") from both tests on one chart:

That is just what I had hoped the chart would look like; actually the results are better than I had hoped. I think my original math predicted 26CFM @ 0 PSI and something like 20CFM @ 40 PSI, but I knew real life would be much less. This is actually closer to the calculated values than it is to my gut feeling of what it would be.

That said, it turns out that the diminishing effect of higher CFM at lower pressures does not cumulatively amount to a whopping gain when you look at tank charge-up time. Here's the data on that:

Tank charge up, 0-140PSI (26gal tank):

Constant speed (60Hz) - 3min 21sec

Constant HP (120-60Hz)- 2min 26sec

Constant HP is 55 seconds (38%) faster.

I was hoping to fill the tank in half the time. Not sure why; that's obviously (now) stupid.

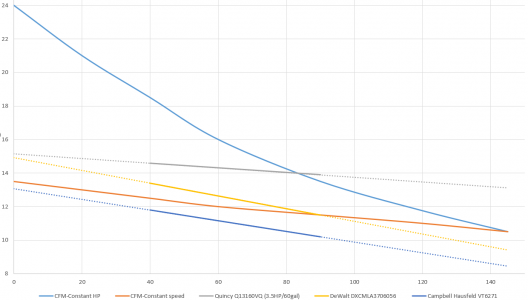

To put the above chart in some context, I've added some other compressors from the market:

1.

Quincy Q13160VQ (3.5HP/60Gal/$850)

2.

DeWalt DXCMLA3706056 (3.7HP/60gal/$779)

3.

Campbell Hausfeld VT6271 (3.2HP/30gal/$599)

Here's a video of a charge/discharge cycle if you're bored enough to watch. Feel free to criticize the unsafe disheveled lair; I've been in full-on obsession mode with this compressor and haven't tidied up since I started. Also it was a minor disaster before I started.

One important thing to note if anyone wants to try and replicate this: there is not exactly a "constant HP" mode in a VFD; at least not in mine. Maybe there is a VFD out there which has such a mode, but I don't know which one. When I was speaking before about constant HP, overspeeding the motor at lower amps, etc., I had maybe lost a bit of my mind. Drives typically have a

constant speed mode and a

constant torque mode.

Constant speed mode will hold the motor at (you guessed it) - a constant speed. Amps/torque can go up or down (

within the envelope of the motor's nameplate parameters) depending on changes in load, but speed will remain the same - so long as the load doesn't get so great that it causes a high amps fault.

Constant torque mode will apply a fixed amount of torque from the motor. Hz/speed can go up or down (

within the envelope of the motor's nameplate parameters) depending on changes in load, but torque will remain the same. If load goes down, speed will increase. If load increases, speed will decrease.

I set out thinking all I needed to do was put the VFD in constant torque mode, set base speed as 60Hz and max speed as 130Hz, and it would automatically behave as I had previously described. It turns out that that ain't how it works. The Yaskawa V1000 VFD that I used does not actually have a bona fide constant torque mode, but it does have a torque limit parameter which theoretically (I thought) should have allowed me to me to achieve an equivalent mode of operation: set a fixed 130Hz reference, and as it bumps up against the torque limit, the speed will decrease. It didn't. What happened was, above 60Hz in the region where available torque is diminished, it was still trying to match the sub-60Hz torque limit. It was trying to achieve nameplate rated torque at double the nameplate rated RPM. No bueno. Here's what that looks like:

Maybe if I had a VFD with a bona fide constant torque mode, the operation above nameplate rated RPM would have been handled automatically as I expected. It's been a long time since I've set up a drive in this manner. I really thought that above nameplate rated RPM they transitioned into a constant power mode. Pretty sure I didn't make that up. But whatever, I knew what I needed: A constant

power mode, wherein speed

and torque are variable,

and it all works even

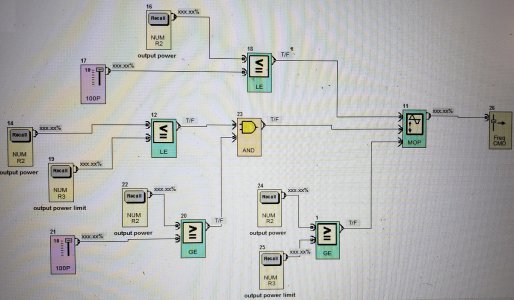

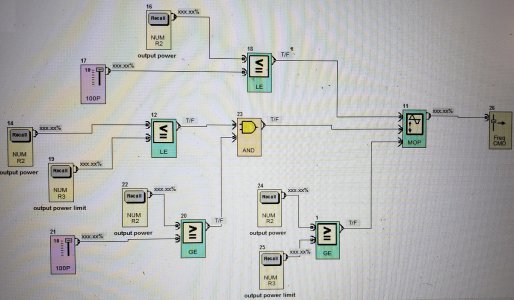

outside the envelope of the motor's nameplate parameters. Since this drive didn't have such a mode, I made it myself. Yaskawa has two different softwares for their VFDs. "Drive Wizard Industrial" is what you saw in the screenshots above; that's the normal drive commissioning/parameter changing software available to anyone. But they have another trick up the sleeve: "DriveWorksEZ." DWEZ is a different, secret-but-not-quite-secret software that speaks to a different, secret-but-not-quite-secret processor on the control board. With this separate software, within this separate processor, you can do some custom programming; write some quasi-"PLC" type functions. Here's the function I wrote to achieve the "Constant Horsepower" mode:

Basically it does this:

1. If output power is greater than 125%, gradually lower speed (override commanded 120Hz speed reference)

2. If output power is between 100% & 125%, gradually raise speed (override commanded 120Hz speed reference)

3. If output power is less than 100%, return to commanded 120Hz speed reference

I bring all this up for 2 reasons; firstly to brag about my kludgey hack solution in the face of poorly made assumptions, and secondly to caution you to go into this better prepared than I did. Make sure that the drive you choose has some kind of constant HP mode which works above 60Hz, or that is has some higher-level programming function like DriveWorksEZ that isn't unobtainium. DriveWorksEZ is unobtainium. I would be remiss if I didn't point that out. They only want Yaskawa-certified techs wielding it. I used to work for a Yaskawa authorized distributor and I was a certified installer; that's why I have the software. You might not be able to get it. Don't just jot down a parts list from this thread and try to replicate it; it could be a costly disappointment.

OK... concept proven I think. Now that's out of the way, I can exit obsession mode and get on with my life, clean my shop, do the things I'm supposed to do. I am back to having a working compressor, even if a hideous abortion of one. I will come back and finish it in small bits as time permits. To Do:

- Weld up unistrut wonder, recover my hardware

- mount unistrut wonder (atop vibration arresting mounts), silencer, air dryer, tank, and an electrical enclosure, on a cart

- troubleshoot Quincy air dryer; may not be operating at 100% capacity

- Install analog pressure sensor, tied into drive or separate PLC. Wire up existing pressure switch as failsafe

- improve zig-zag heat exchanger, wire wrap, etc.

- finish silencer concept

- Install temperature sensors in key areas

- program other modes of operation, like re-charge

- Fabricate a metal shroud for it