Ok, allow me to steer this out of theory zone and into action. Disregard all previous talk of 240Hz and overspeeding the compressor head by 4x its rated RPM.

I've chosen a 3hp motor from among my cache and just picked up a

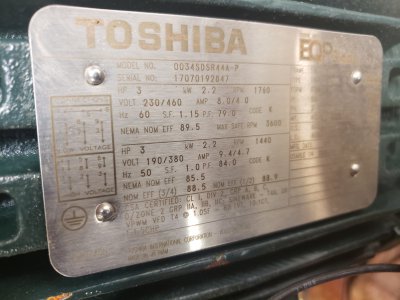

5hp compressor head from HF. As you can see on the motor nameplate, it's a 1760RPM/60Hz motor motor with a stated maximum safe speed of 3600RPM. So I should safely be able to run it up to 123Hz. But I'm getting a strong "I live life 10% over the edge" vibe from this motor so let's say 135Hz/3,960RPM is my max.

My compressor head is 1050RPM max, 650RPM min (for cooling I guess?), 17.3 CFM @ 40 PSI, 15.2 CFM @ 90 PSI, and has a 14.5" flywheel. Since the compressor overspeed condition only happens at the beginning of charging an empty tank, I feel comfortable overpseeding it by ... uh.. (arbitrarily) 25%. Unlike the motor which stands a real chance of centrifugal forces pulling itself apart, I'm not too worried about the compressor failing with an occasional 25% overspeed condition. So call it 1313RPM max.

So... (1313RPM × 14.5")/3960RPM = 4.8" motor pulley diameter. They didn't have a pulley that size at Tractor Supply so I got a 4.5" pulley. Looks like with a 4.5" motor pulley at 3960RPM I'll only be able to overspeed the compressor by 17% (1229RPM). Shame. Anyway, still looking good.

In the beginning before any pressure builds, I think the volume is a direct function of cylinder displacement. So with a 3.14" bore, 2.36" stroke, and two cylinders (36.52C.I.D.), at 1229 RPM, I should be moving 44,883 cubic inches/min (26CFM) from zero PSI. By the time 40PSI is reached, I estimate we should still be below the 3HP threshold and therefore still running 17% excess compressor RPM and therefore the rated 17.3CFM becomes 20.2CFM.

Somewhere between 40PSI and 90PSI, I estimate, is where we max out the 3HP motor's power and RPM starts to drop off. Wherever that point is (I haven't done the math on that yet, I think I'll just discover it empirically) this turns into a 3HP compressor. But it's still a 3HP compressor spinning way above 1760 RPM and moving a lot more air, a lot sooner in the process, than a normal 3HP compressor. Right at the point before cut-off, is when the speed finally is pulled down to the 1760 nameplate RPM, and when it finally becomes a 3HP compressor, moving the same amount of air as a standard 3HP compressor; it's just a 3HP compressor geared down to turn a 5HP head. And then it shuts off. So it only spends a few seconds being the good little boy that the nameplate advertised. All the rest of time it's being a very, very bad boy.

All that sound more reasonable than the wacky numbers I spouted in the OP? Anyone wanna make a prediction about operation? Be careful now; if you opt to say nay, realize that we are no longer in theory mode and you might be eating crow in short order.