- Joined

- Oct 21, 2017

- Messages

- 504

From what I can visualize, should work right to left in forward rotation or upside down left to right as you are wanting

You'd think so wouldn't you?

From what I can visualize, should work right to left in forward rotation or upside down left to right as you are wanting

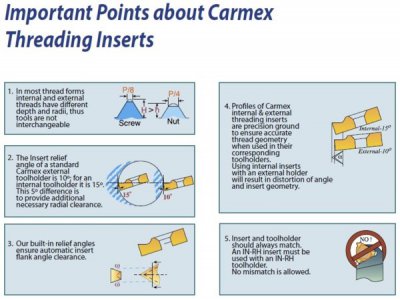

Hi, would you mind sharing where you get this pic?EDIT: Please see the diagram.

If you have a screw-on chuck, be careful that it does not unscrew.

View attachment 263164

Ray

I didn't post the pic but I believe its from the Carmex website.Hi, would you mind sharing where you get this pic?

Left hand and right hand bars are commercially available with the appropriate inserts for threading in all directions for left hand and right hand threadsI've never seen inserts used to cut on the trailing edge - away from the chuck. There is no clearance on the trailing edge as they are tilted the wrong way in the toolholder. Threading away from the chuck looks cool, but not for insert tooling.

I haven't looked into what is now available, I do know that left hand and right hand threads whether internal or external can be produced cutting towards the chuck but with the rotation reversed, always on the leading edge of the insert.Left hand and right hand bars are commercially available with the appropriate inserts for threading in all directions for left hand and right hand threads