- Joined

- Nov 24, 2017

- Messages

- 64

Hello Again,

Sorry for all the questions, I hope they are constructive and that others will also read and benefit from my newbeness.

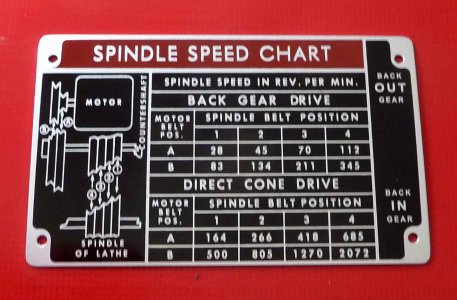

I'm trying to figure out what the actual spindle speeds are for each of the pulley and gear positions.

The machine is an Atlas V42 and I have figured out that it is a 10F.

Firstly the motor has 1435 RPM Stamped on it.

I also notice that the motor and the next pulley both have two positions however both pulleys are larger than the ones currently in use so it would seem I need a different sized belt to use them. (See attached)

Is this standard or an add on feature?

I have been looking through a manual I found online "Manual of Lathe Operation and Machinist Tables" and can't find anything about what rpm each of the pulley positions actually produce.

With the 4 major pulley positions and the back gears, this would produce 8 speeds.

With the second pulley on the motor this would bring the number of different speeds to 16.

I'd like to be able to calculate a rough surface speed based on the type of tools I'm using and the diameter I'm turning.

Has anyone got a clue where I can start to figure out all the possible speeds?

Thanks

David

PS I made my first test cut today after 30 Years out of the trade. Bit of a mile stone really

(Nothing exploded)

Sorry for all the questions, I hope they are constructive and that others will also read and benefit from my newbeness.

I'm trying to figure out what the actual spindle speeds are for each of the pulley and gear positions.

The machine is an Atlas V42 and I have figured out that it is a 10F.

Firstly the motor has 1435 RPM Stamped on it.

I also notice that the motor and the next pulley both have two positions however both pulleys are larger than the ones currently in use so it would seem I need a different sized belt to use them. (See attached)

Is this standard or an add on feature?

I have been looking through a manual I found online "Manual of Lathe Operation and Machinist Tables" and can't find anything about what rpm each of the pulley positions actually produce.

With the 4 major pulley positions and the back gears, this would produce 8 speeds.

With the second pulley on the motor this would bring the number of different speeds to 16.

I'd like to be able to calculate a rough surface speed based on the type of tools I'm using and the diameter I'm turning.

Has anyone got a clue where I can start to figure out all the possible speeds?

Thanks

David

PS I made my first test cut today after 30 Years out of the trade. Bit of a mile stone really

(Nothing exploded)