- Joined

- Jun 29, 2014

- Messages

- 4,173

I've been dabbling in FCAW for a little over a year now and I purchased all of my tools and equipment at Harbor Freight. Their little Titanium 125 has been very easy to use and with my limited experience - appears to work quite well for my needs.

Well, all of this pent up confidence has me welding, welding, welding! My next big project will require LOTS of welding a tube frame and the welds need to be good - at least by my hobby standards. So, I figure I need to two things for my next big project to be successful: 1) Practice, Practice, Practice and 2) a decent welding table to work from.

I purchased the Harbor Freight folding welding table and while it is OK for small stuff that doesn't have to be EXACTLY square - the table just isn't flat. It's also low, I would like a surface that is a little higher up so standing and welding isn't so much work on my lower back.

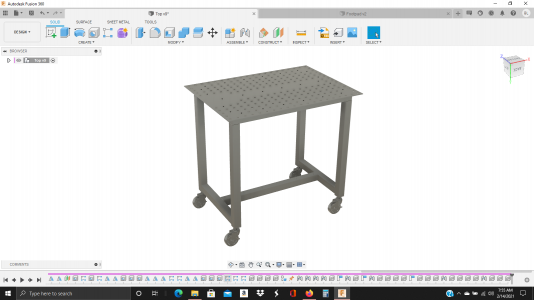

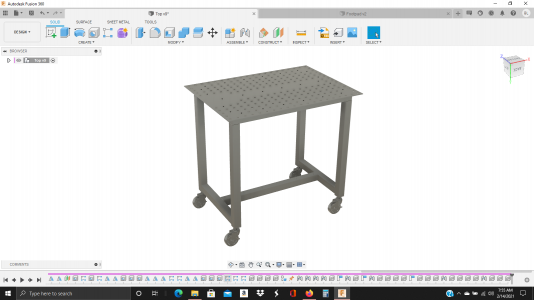

Anyway, here is the mockup in Fusion 360:

It stands about 40" high. The top is about 40" long, 28" deep and is 3/16" thick stainless. The legs are 2" x 2" x 3/16" wall steel tube. Overkill yes, but that feature is my practice for the bigger project coming in the next few weeks.

I purchased some 4" casters with 1/2-20 stems, 120lb. capacity each with locking casters and rubber wheels. OK, less talking - more photos!

Here is a video of the top being cut on the laser:

Total cut time was about 15 minutes. There was some slag on the back of the holes and edges that took me about 20 minutes to remove with the angle grinder. Normally, if this were not a one-off, the tech would fine tune the program to eliminate slag.s

Finished top:

Cutting up the tubes on my new "cold saw". Not a traditional cold saw. Evolution S389CPS. It's sort of a blend of cold saw and an abrasive cut-off saw. It runs slower at 1450rpm, uses a carbide 14" saw blade and uses the same abrasive saw cutting action. I can't get over how easy this thing is to use AND how accurate AND fast it is. I spent more time measuring and laying out the angles than I did cutting.

More to come in the next day or two.

Well, all of this pent up confidence has me welding, welding, welding! My next big project will require LOTS of welding a tube frame and the welds need to be good - at least by my hobby standards. So, I figure I need to two things for my next big project to be successful: 1) Practice, Practice, Practice and 2) a decent welding table to work from.

I purchased the Harbor Freight folding welding table and while it is OK for small stuff that doesn't have to be EXACTLY square - the table just isn't flat. It's also low, I would like a surface that is a little higher up so standing and welding isn't so much work on my lower back.

Anyway, here is the mockup in Fusion 360:

It stands about 40" high. The top is about 40" long, 28" deep and is 3/16" thick stainless. The legs are 2" x 2" x 3/16" wall steel tube. Overkill yes, but that feature is my practice for the bigger project coming in the next few weeks.

I purchased some 4" casters with 1/2-20 stems, 120lb. capacity each with locking casters and rubber wheels. OK, less talking - more photos!

Here is a video of the top being cut on the laser:

Total cut time was about 15 minutes. There was some slag on the back of the holes and edges that took me about 20 minutes to remove with the angle grinder. Normally, if this were not a one-off, the tech would fine tune the program to eliminate slag.s

Finished top:

weld tabletop.png

3/16" thick 304 stainless topper for welding table - 40" x 28"

Cutting up the tubes on my new "cold saw". Not a traditional cold saw. Evolution S389CPS. It's sort of a blend of cold saw and an abrasive cut-off saw. It runs slower at 1450rpm, uses a carbide 14" saw blade and uses the same abrasive saw cutting action. I can't get over how easy this thing is to use AND how accurate AND fast it is. I spent more time measuring and laying out the angles than I did cutting.

More to come in the next day or two.