- Joined

- Dec 18, 2019

- Messages

- 7,320

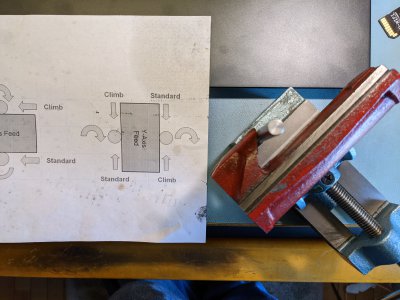

Oh, foo, minor disaster. I was taking off 0.005" at a time, everything went well until the mill hit a hard spot or something. I had taken off 0.035", 0.005" at a time, without a problem. The surface was ok. When the mill hit the hard spot, it dove in and pulled the piece up from the vise about 0.100". Exciting in a bad way. There's plenty of meat left to take out the somewhat cylindrical divot, but it is disappointing nonetheless. Coming in that way should not be climb milling right? Normal rotation, workpiece to the left and cutting from back to front? I wasn't even near the end, where I would slow the feed rate. My feed rate was really slow, by the way, like about 0.5" per minute. I really was taking it easy. Once I slow my heart down, I'll go at it again.

Ball came out nice, first pass. I have 49 extra of them, but only 1 nut, so I have to rescue the nut.

Obviously did something wrong, what was it? Not eager to make the same mistake. Milling 0.005" but with 1.5" LOC?

Ball came out nice, first pass. I have 49 extra of them, but only 1 nut, so I have to rescue the nut.

Obviously did something wrong, what was it? Not eager to make the same mistake. Milling 0.005" but with 1.5" LOC?

I need to make my own picture, that even I can follow.

I need to make my own picture, that even I can follow.