- Joined

- Dec 18, 2019

- Messages

- 7,320

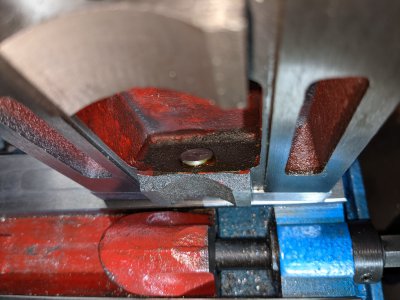

My middling vise, SKU: VISE-4in-HIGHPREC seems to have more jaw lift than I'd like. Is there any adjustment that could be made to reduce the lift? When I purchased my PM25 last year, PM's best vise was either out of stock, or back ordered.

I do have a 3" toolmaker's vise, which I like a lot. The lift is significantly less than the vise above. But it's more limited in things I can clamp. Is there anything that came be done to "fix" the 4 inch vise? Or should I just use it as a general purpose vise in the garage, and get a better one?

I do have a 3" toolmaker's vise, which I like a lot. The lift is significantly less than the vise above. But it's more limited in things I can clamp. Is there anything that came be done to "fix" the 4 inch vise? Or should I just use it as a general purpose vise in the garage, and get a better one?