- Joined

- Feb 2, 2013

- Messages

- 3,954

I finally got around to doing the retrofit on my Shenwai SW900B 1236 lathe

it came with a 1.5 hp(ish) 115v/220v single phase motor, as the OEM powerplant. i had to change that

i surfed the site that sounds a lot like E-PAY, and found an inverter rated 2 hp motor by Marathon, very inexpensively

then i found an inexpensive VFD to go with it!

Shen Zhen Ecogoo 9000 , single phase 220v input, 3 phase 220v output

i ran a test on the pairing and made a video of the test and minor parameter setting

after the test, i considered what pulley size to use.

the OEM pulley is a 2 step pulley, 2.25" on the first step, 4-3/8" on the second step.

i decided to use a single step pulley at 2" diameter, here is why...

the 2" pulley is smaller than the stock pulley and therefore will require more motor speed to achieve the equivalent spindle speed,

so when running low spindle speeds, the motor is still turning at a faster rpm and has more HP available than if the stock pulley was utilized.

i rarely use the high speed pulley arrangement, so i'll allow the retrofit motor(1725rpm) to run up to 90Hz (2587 rpm) for my limited high speed needs.

the next part was removal of the old motor and the control panel

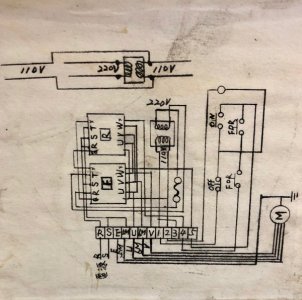

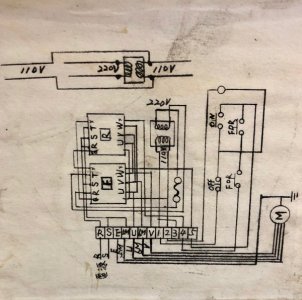

( I included the OLD wiring diagram for those interested)

i mounted the VFD in the OEM control box

then wired in the VFD.

i'm utilizing the OEM apron switch

then i plugged her in for a test run!

i made a short video of the fire up!

the retrofit was successful

i'll be utilizing the vfd from 10 to 90Hz.

thanks for looking!

it came with a 1.5 hp(ish) 115v/220v single phase motor, as the OEM powerplant. i had to change that

i surfed the site that sounds a lot like E-PAY, and found an inverter rated 2 hp motor by Marathon, very inexpensively

then i found an inexpensive VFD to go with it!

Shen Zhen Ecogoo 9000 , single phase 220v input, 3 phase 220v output

i ran a test on the pairing and made a video of the test and minor parameter setting

after the test, i considered what pulley size to use.

the OEM pulley is a 2 step pulley, 2.25" on the first step, 4-3/8" on the second step.

i decided to use a single step pulley at 2" diameter, here is why...

the 2" pulley is smaller than the stock pulley and therefore will require more motor speed to achieve the equivalent spindle speed,

so when running low spindle speeds, the motor is still turning at a faster rpm and has more HP available than if the stock pulley was utilized.

i rarely use the high speed pulley arrangement, so i'll allow the retrofit motor(1725rpm) to run up to 90Hz (2587 rpm) for my limited high speed needs.

the next part was removal of the old motor and the control panel

( I included the OLD wiring diagram for those interested)

i mounted the VFD in the OEM control box

then wired in the VFD.

i'm utilizing the OEM apron switch

then i plugged her in for a test run!

i made a short video of the fire up!

the retrofit was successful

i'll be utilizing the vfd from 10 to 90Hz.

thanks for looking!