Hi all,

My name is Adam - a (soon to be graduated) mechanical engineer who got sucked into the hobby of building a CNC mill. I started a PM-25MV conversion roughly a year ago and I am the definition of a long-time forum lurker. I have spent hours upon hours reading and researching through forums without ever giving much feedback or response so I've decided to change that. I've always wanted to make a build thread to document my progress and hopefully be a resource for people who want to do their own conversion. Although they definitely don't know me, I wanted to give a shoutout to @macardoso, @shooter123456 and @ChrisAttebery. I remember even before I purchased my mill I spent hours studying their build threads and various pictures to formulate my own plan on how to go about converting my machine. Hopefully, I can add to the repository of pm25/g0704 mill conversions out there.

At this point in time, my mill is fully functioning and I couldn't be happier with it (although I will always find upgrades to do). I have a ton of pictures saved and thus I expect this thread to be very picture focused. Throughout my conversion, I have changed up components that I didn't like/had bad luck with and I hope to show my mistakes.

Here is a sneak peek at what I'll be building this thread up to +more as my mill continues to evolve:

Some current specs at the time of writing this:

Like many, I started with a brand new PM25MV and quickly went to work disassembling and noting down dimensions. I chose a PM over the G0704 for one main reason: the spindle belt drive. I read on numerous occasions that the quality control of the PM variant was slightly superior to the Grizzly, but with time, I have come to realize that probably isn't true (for the money, they are both great machines).

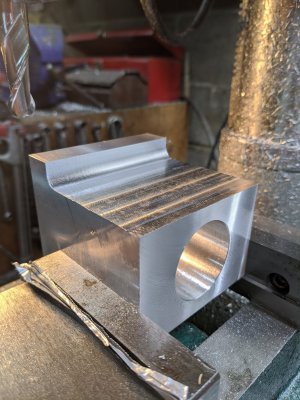

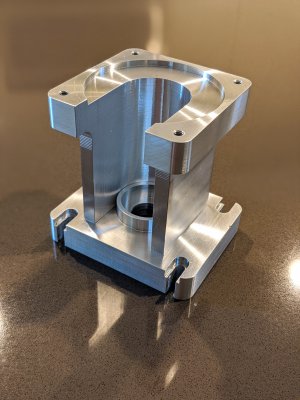

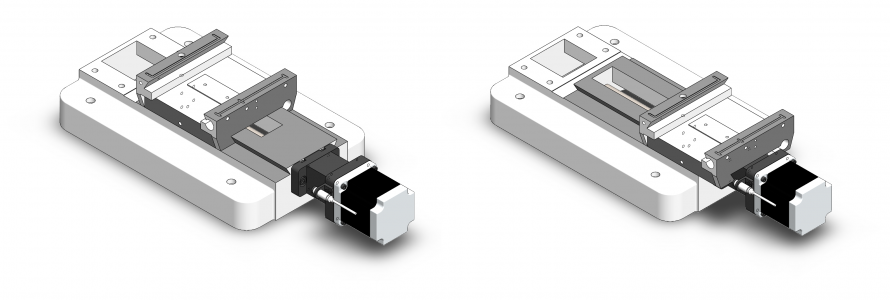

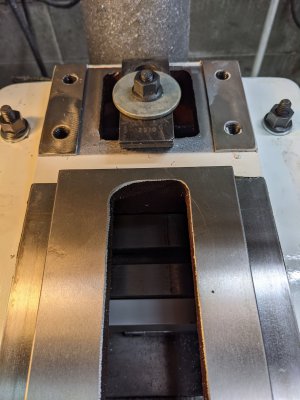

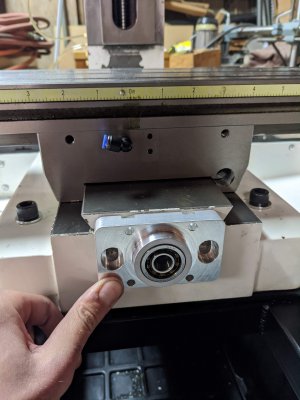

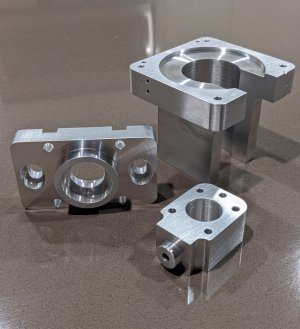

I began designing and building the stand that my mill would permanently live on. I always envisioned a full enclosure with hopes to implement flood coolant in the future and I wanted direct access to the Y ballscrew from underneath the mill and so the table reflects that. While building the stand I began designing all the motor and ballscrew mounts.

The stand is made from 1.5"x1.5" HSS tubing. It's definitely overkill since it probably weighs close to 150-200lbs, but psychologically it makes the mill feel more rigid and sturdy.

The chip trays are all sloped towards the middle of the table. Some angle iron was added to the large opening so that I could easily slide in/out a large container that catches all the chips.

My name is Adam - a (soon to be graduated) mechanical engineer who got sucked into the hobby of building a CNC mill. I started a PM-25MV conversion roughly a year ago and I am the definition of a long-time forum lurker. I have spent hours upon hours reading and researching through forums without ever giving much feedback or response so I've decided to change that. I've always wanted to make a build thread to document my progress and hopefully be a resource for people who want to do their own conversion. Although they definitely don't know me, I wanted to give a shoutout to @macardoso, @shooter123456 and @ChrisAttebery. I remember even before I purchased my mill I spent hours studying their build threads and various pictures to formulate my own plan on how to go about converting my machine. Hopefully, I can add to the repository of pm25/g0704 mill conversions out there.

At this point in time, my mill is fully functioning and I couldn't be happier with it (although I will always find upgrades to do). I have a ton of pictures saved and thus I expect this thread to be very picture focused. Throughout my conversion, I have changed up components that I didn't like/had bad luck with and I hope to show my mistakes.

Here is a sneak peek at what I'll be building this thread up to +more as my mill continues to evolve:

Some current specs at the time of writing this:

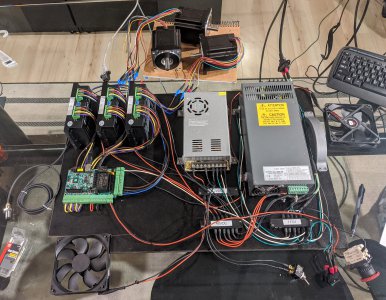

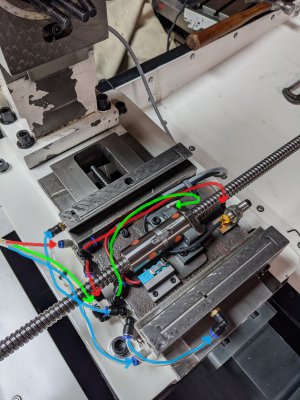

- 906oz NEMA34 stepper motors on X and Y

- 1200oz NEMA34 stepper motor on Z

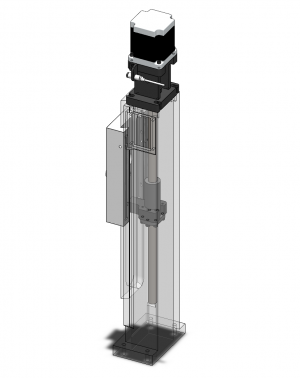

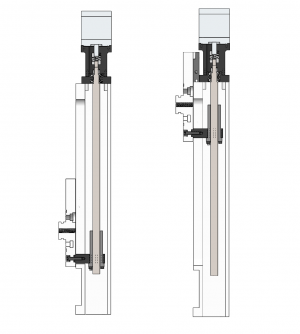

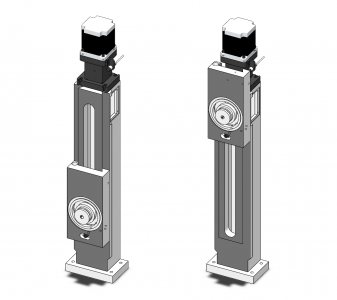

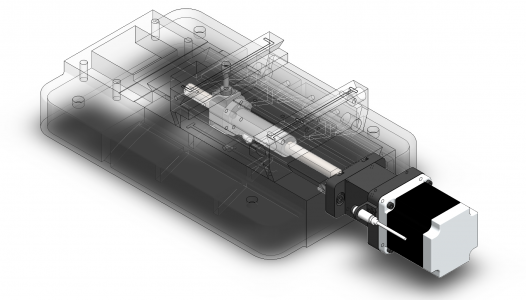

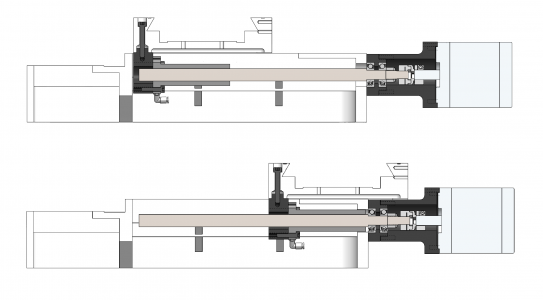

- 1605 OFU ballscrews on X and Y with 2005 OFU ballscrew on Z (C5 ground with 5% preload)

- Pokeys57CNC motion controller running Mach4

- 2.2kW BLDC motor with a custom 2 speed belt drive

- Pneumatic power drawbar

- Homebuilt mist coolant

Like many, I started with a brand new PM25MV and quickly went to work disassembling and noting down dimensions. I chose a PM over the G0704 for one main reason: the spindle belt drive. I read on numerous occasions that the quality control of the PM variant was slightly superior to the Grizzly, but with time, I have come to realize that probably isn't true (for the money, they are both great machines).

I began designing and building the stand that my mill would permanently live on. I always envisioned a full enclosure with hopes to implement flood coolant in the future and I wanted direct access to the Y ballscrew from underneath the mill and so the table reflects that. While building the stand I began designing all the motor and ballscrew mounts.

The stand is made from 1.5"x1.5" HSS tubing. It's definitely overkill since it probably weighs close to 150-200lbs, but psychologically it makes the mill feel more rigid and sturdy.

The chip trays are all sloped towards the middle of the table. Some angle iron was added to the large opening so that I could easily slide in/out a large container that catches all the chips.

Last edited: