- Joined

- Jul 9, 2014

- Messages

- 613

Ben,

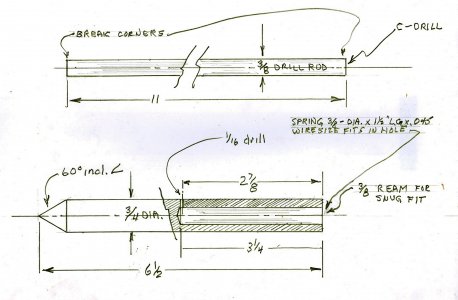

thanks for that , I can imagine the device you describe . I did have a bit of a fiddle chucking up the four jaw chuck to turn a face off centre on some 1.25 " hex bars , any chance of a picture or hand drawn sketch ?

I was thinking of using the chuck fitted with a bar turned to a point to trap things in place but the sliding piston & spring idea sound even better . Especially if the bar is scalloped out over an inch or so , so you can slip a pin in the rod to retain the piston permanently .

I had a lapse this afternoon & evening and went back to making the holder for the laser pointer.

It works well , has six alignment screws as two sets of evenly spaced alignment adjuster (three ) screws at the back and 60 degrees out of this alignment 25 mm forward of the back ones at the front is another set of three alignment screws . I played for about 2 minutes set it up but the beam was still half way up the chuck , judicious application of a lump of wood soon solved this little problem . The 1 mm laser spot now shines in the pinhole where the precision ground chuck jaws meet .

I took it out the tail stock , rotated it 180 degree and shoved it back , it's still in perfect alignment .

I spent the last hour chucking up the hex bar for the off centre turning of my face plate clamping devices and actually managed to chip off the first 1/4 inch some 10 mm deep having set the back gear & spindles up to give me about one rev per 1 . 5 seconds .

This face plate exercise is starting to come together , I can't wait to get back to it all after the weekend .

Piccies to follow tomorrow hopefully showing disasters 1,2 & 3 then the final modified solution.

thanks for that , I can imagine the device you describe . I did have a bit of a fiddle chucking up the four jaw chuck to turn a face off centre on some 1.25 " hex bars , any chance of a picture or hand drawn sketch ?

I was thinking of using the chuck fitted with a bar turned to a point to trap things in place but the sliding piston & spring idea sound even better . Especially if the bar is scalloped out over an inch or so , so you can slip a pin in the rod to retain the piston permanently .

I had a lapse this afternoon & evening and went back to making the holder for the laser pointer.

It works well , has six alignment screws as two sets of evenly spaced alignment adjuster (three ) screws at the back and 60 degrees out of this alignment 25 mm forward of the back ones at the front is another set of three alignment screws . I played for about 2 minutes set it up but the beam was still half way up the chuck , judicious application of a lump of wood soon solved this little problem . The 1 mm laser spot now shines in the pinhole where the precision ground chuck jaws meet .

I took it out the tail stock , rotated it 180 degree and shoved it back , it's still in perfect alignment .

I spent the last hour chucking up the hex bar for the off centre turning of my face plate clamping devices and actually managed to chip off the first 1/4 inch some 10 mm deep having set the back gear & spindles up to give me about one rev per 1 . 5 seconds .

This face plate exercise is starting to come together , I can't wait to get back to it all after the weekend .

Piccies to follow tomorrow hopefully showing disasters 1,2 & 3 then the final modified solution.

![big ball[1].jpg big ball[1].jpg](https://www.hobby-machinist.com/data/attachments/42/42764-7bb5f87b5eddcc019c5a345ec752acdd.jpg)