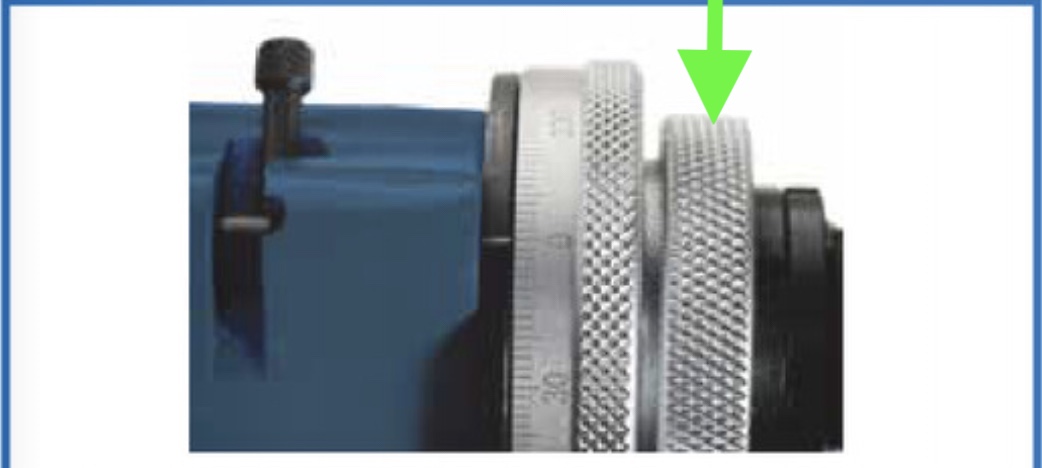

On my Universal grinder there's a lock ring just above the ring/handle to tighten the 5C collets. If I loosen it, it allows the degree wheel to free spin, so I can zero it out and then re-lock it into position.

-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Universal Cutter Grinder Malfunction?

- Thread starter PabloMack

- Start date

- Joined

- Nov 17, 2019

- Messages

- 22

> C-Bag: why would you want 7deg out of curiosity.

It would allow you to precisely lock an angle after setting to exactly horizontal or some other starting place. I can't say as a beginner why I would want to do that but it would give you complete control over locking at measured angles that the machine doesn't seem to have. I suppose that the starting place just has to be done by rotating the bit in the collet before drawing it down while locked at one of the 15° lstop points (say at 0°). Then your flutes are brought to bear by using the other stop points (24 in total).

It would allow you to precisely lock an angle after setting to exactly horizontal or some other starting place. I can't say as a beginner why I would want to do that but it would give you complete control over locking at measured angles that the machine doesn't seem to have. I suppose that the starting place just has to be done by rotating the bit in the collet before drawing it down while locked at one of the 15° lstop points (say at 0°). Then your flutes are brought to bear by using the other stop points (24 in total).

Last edited:

- Joined

- Nov 17, 2019

- Messages

- 22

> DAT510: On my Universal grinder there's a lock ring just above the ring/handle to tighten the 5C collets...

I have no experience with 5C collets and assumed that was what my machine used. But now I know that the collets my machine uses are quite a bit smaller and aren't in the "C series". They are some special type of collet that Deckel sharpeners use and are cloned by the Chinese. Before I knew what I know now, I ordered a 5C collet to ER20 adapter. I immediately realized my mistake when it arrived and saw that 5C is quite large. If I had just looked at a 5C mechanical drawing and compared it to the 3 collets that came with the machine first then I wouldn't have spent the $40+ on a collet I have no machine for.

I have no experience with 5C collets and assumed that was what my machine used. But now I know that the collets my machine uses are quite a bit smaller and aren't in the "C series". They are some special type of collet that Deckel sharpeners use and are cloned by the Chinese. Before I knew what I know now, I ordered a 5C collet to ER20 adapter. I immediately realized my mistake when it arrived and saw that 5C is quite large. If I had just looked at a 5C mechanical drawing and compared it to the 3 collets that came with the machine first then I wouldn't have spent the $40+ on a collet I have no machine for.

Last edited:

- Joined

- Feb 9, 2017

- Messages

- 5,523

as part of my deep research on this style machine I found the original Deckel style collets are worthless to me because they are metric and odd. And don’t even go up to 1/2” only 12mm. So I found one that was R8 and was not aware there was one with 5c. I found I couldn’t just order the R8 head and have it fit the Deckel style dovetails. They are not universal.I have no experience with 5C collets and assumed that was what my machine used. But now I know that the collets my machine uses are quite a bit smaller and aren't in the "C series". They are some special type of collet that Deckel sharpeners use and are cloned by the Chinese. Before I knew what I know now, I ordered a 5C collet to ER20 adapter. I immediately realized my mistake when it arrived and saw that 5C is quite large. If I had just looked at a 5C mechanical drawing and compared it to the 3 collets that came with the machine first then I wouldn't have spent the $40+ on a collet I have no machine for.

Anything that causes overhang like trying to adapt to like ER is worthless to me also as the amount of x on this machine is very limited so adapters are no go. ER itself causes all kinds of overhang because of the nut. Notice all the other collets are tightened from the rear making for no overhang interference.

Trying to understand beforehand exactly the parameters before I bought was next to impossible at that time as there was no vids on YT except on the Deckel itself which was all about grinding D bits.

- Joined

- Nov 17, 2019

- Messages

- 22

C-Bag: I have experienced many of the same things you describe. My case is a bit different than yours because my machine is small (and "mostly" metric) and will probably never use an end mill bit larger than 3/8". Also, I do as much in metric as I can. But because I am in the USA I buy cutters and stock in imperial because it is cheaper and more available. I think because my sharpener uses a Deckel type collet it is a smaller unit and it probably accounts for it being as cheap as it was. Even so, it is so heavy that it took some risk to my health to get it up the stair way and up onto the counter where it now sits. I wouldn't want it to be any larger (and heavier) than it already is. Pretty much all the work I do is CNC. So, even though I like to dream about having a larger machine, the price gap seems to sky-rocket (and the choices narrow) when you insist on CNC. It seems you almost have to do the conversion yourself. Most of the large CNC machines seem to be bundled with all of the control and software which drives the price way up and locks you into the manufacturers's way of doing everything. I wrote the control software I use and put the electronics together myself so I don't need or want the bundled controls. If worst came to worst, I could buy the next smaller metric collet and grind or file the opening larger to fit the imperial size bit I want (of course with the risk of losing accuracy). So far I've only found 1/4", 1/8" and even 1/2" collets in the sizes offered for imperial. But I don't use many cutter sizes so I don't need anywhere close to what might be considered to be a "full set". The offering on EBay does show going up to 16mm in metric. The web page does show a mechanical drawing and so I am pretty sure that these collets will fit my machine. I have a 1/4" on order so I will find out very soon whether or not I've made another mistake.

Dat510: I'll watch the videos. Thanks.

Dat510: I'll watch the videos. Thanks.

Last edited:

- Joined

- Feb 9, 2017

- Messages

- 5,523

There is no size difference between the various collet mods. They all weigh about 110lbs and I did strain my bicep wrestling that thing on to the bench.C-Bag: I have experienced many of the same things you describe. My case is a bit different than yours because my machine is small (and "mostly" metric) and will probably never use an end mill bit larger than 3/8". Also, I do as much in metric as I can. But because I am in the USA I buy cutters and stock in imperial because it is cheaper and more available. I think because my sharpener uses a Deckel type collet it is a smaller unit and it probably accounts for it being as cheap as it was. Even so, it is so heavy that it took some risk to my health to get it up the stair way and up onto the counter where it now sits. I wouldn't want it to be any larger (and heavier) than it already is. Pretty much all the work I do is CNC. So, even though I like to dream about having a larger machine, the price gap seems to sky-rocket (and the choices narrow) when you insist on CNC. It seems you almost have to do the conversion yourself. Most of the large CNC machines seem to be bundled with all of the control and software which drives the price way up and locks you into the manufacturers's way of doing everything. I wrote the control software I use and put the electronics together myself so I don't need or want the bundled controls. If worst came to worst, I could buy the next smaller metric collet and grind or file the opening larger to fit the imperial size bit I want (of course with the risk of losing accuracy). So far I've only found 1/4", 1/8" and even 1/2" collets in the sizes offered for imperial. But I don't use many cutter sizes so I don't need anywhere close to what might be considered to be a "full set". The offering on EBay does show going up to 16mm in metric. The web page does show a mechanical drawing and so I am pretty sure that these collets will fit my machine. I have a 1/4" on order so I will find out very soon whether or not I've made another mistake.

Dat512: I'll watch the videos. Thanks.

The first machine I bought off eBay was the Deckel style collets. Between the silly mistakes in how they word things and the seller not really understanding English and not really having any experience they sold me the wrong machine. So it seemed no matter how I tried to avoid a mess I still fell in it. That’s why I know I couldn’t just change the head from Deckel to R8.

After a couple of months of back and forth and a trip down to their warehouse in LA and physically swapping it out for the R8 machine I was finally done.

We are truly apples and oranges here as I’m 99% imperial and all manual. My mill drill I regularly use 3/4” and 1/2” shank mill bits in it. And I went R8 because that’s what my mill drill is. I’m happy with it because it does what I need and doesn’t take up hardly any room.

- Joined

- Nov 17, 2019

- Messages

- 22

C-Bag: I'm glad you got it sorted out. May I ask how much you paid for your R8 grinder? Mine was $749. Shipping was cheap (and low risk) because they had a warehouse in Houston where I live. It was just a short truck drive away and I greeted them at the door. After buying some things from Grizzly, I have grown to expect a couple of things to be broken for heavy items like these because, even the guys who do the shipping, probably aren't orders of magnitude stronger than I am. When they drop things it's no skin off their noses and they know their company will just get more business because it means there will be more shipping. And companies like Grizzly don't want to just ship and replace the parts that are broken. They want you to ship the whole unit back so that you can get a heavy replacement with another set of broken parts in it and do the haggling all over again. I think the people who run their shipping departments aren't very smart to start with.

I went through this whole ordeal just a month ago with my arbor press. They were good enough to "inspect" the unit before shipping the replacement. The defects with the unit I sent back were certainly not caused by shipping. Every fourth tooth on the rack was cut with an offset of 1.3mm from what it should have been. I suspect that Grizzly will probably try to sell the defective unit to somebody who doesn't complain about it.

Does your unit run off 110 or 220 AC? My unit was billed at 90 lb. shipping weight. Because the attachments and other stuff probably weighs about 10 lb. then I'm guessing that my unit is probably only about 80 lb. I might be wrong on that.

As you say, the "over-hang" could be a problem for me. I think that the only case where it becomes critical to have collets with short noses is when you need to grind a radius on something. I don't think that is needed with end-mill grinding so I can back the assembly off and get all the leeway I need to grind flat surfaces at any reasonable angle. I'm still a rookie and learning so I may yet have a pit hole waiting for me.

I went through this whole ordeal just a month ago with my arbor press. They were good enough to "inspect" the unit before shipping the replacement. The defects with the unit I sent back were certainly not caused by shipping. Every fourth tooth on the rack was cut with an offset of 1.3mm from what it should have been. I suspect that Grizzly will probably try to sell the defective unit to somebody who doesn't complain about it.

Does your unit run off 110 or 220 AC? My unit was billed at 90 lb. shipping weight. Because the attachments and other stuff probably weighs about 10 lb. then I'm guessing that my unit is probably only about 80 lb. I might be wrong on that.

As you say, the "over-hang" could be a problem for me. I think that the only case where it becomes critical to have collets with short noses is when you need to grind a radius on something. I don't think that is needed with end-mill grinding so I can back the assembly off and get all the leeway I need to grind flat surfaces at any reasonable angle. I'm still a rookie and learning so I may yet have a pit hole waiting for me.

Last edited:

- Joined

- Feb 9, 2017

- Messages

- 5,523

When all was said and done it was $750. The original wrong machine was $625. The amount of bait and switch was exasperating and became part of the haggle. Here they sent me the wrong machine when their poorly worded ad with things misspelled strategically it seemed like, mixes of metric and imperial ,an assurance the “collects” would go up to .750 inches all while dealing with a person through a translation program halfway around the world. What could go wrong?

The game was no fun as I thought I’d done my homework. They would always start out with oh you can return the machine and get my $$ back and my happiness is paramount. I don’t have the pics anymore but they might have well sent the grinder in a paper bag. Thin cardboard with like 1/4” of styrofoam on the inside which was dust when it got here. When I asked would I be liable for damage if I sent it back, of course. So I drove it down to LA, almost 6hr round trip through road warrior territory. I didn’t know it but it was graduation weekend.

This machine is 110v, the first was 220. I made the mistake of buying the flute grinding attachment for the last $50 of the $750 total. Total waste of $$. I had read here if it’s not an air bearing, it won’t work. It isn’t and pretty much didn’t. Lesson learned. Picked up a freestanding air bearing flute attachment for $200. Of course it won’t fit the U2, but I’ll adapt it to one of my other grinders.

I love the fact I’ve been able to fix 10 or so dull and broken endmills that came with my mill. Along with resharpening my first endmill set and never get stumped by a dull tool or needing a special grind. Like grinding a flatter angle for brass or a flat end for facing or counter sinking a bolt hole. I’ve now got drawers of rescued endmills I got out of my brothers scrap bin for free. Gotta spend $$ to be cheap.

i have learned a lot and the machine has turned out to be even more useful than I first thought. So it was worth the struggle as it has the smallest footprint and with a bit of thought a lot of capability. If a Darex with an air bearing, or a small Gorton for the same say $800 I would have jumped at them, but they didn’t.

The game was no fun as I thought I’d done my homework. They would always start out with oh you can return the machine and get my $$ back and my happiness is paramount. I don’t have the pics anymore but they might have well sent the grinder in a paper bag. Thin cardboard with like 1/4” of styrofoam on the inside which was dust when it got here. When I asked would I be liable for damage if I sent it back, of course. So I drove it down to LA, almost 6hr round trip through road warrior territory. I didn’t know it but it was graduation weekend.

This machine is 110v, the first was 220. I made the mistake of buying the flute grinding attachment for the last $50 of the $750 total. Total waste of $$. I had read here if it’s not an air bearing, it won’t work. It isn’t and pretty much didn’t. Lesson learned. Picked up a freestanding air bearing flute attachment for $200. Of course it won’t fit the U2, but I’ll adapt it to one of my other grinders.

I love the fact I’ve been able to fix 10 or so dull and broken endmills that came with my mill. Along with resharpening my first endmill set and never get stumped by a dull tool or needing a special grind. Like grinding a flatter angle for brass or a flat end for facing or counter sinking a bolt hole. I’ve now got drawers of rescued endmills I got out of my brothers scrap bin for free. Gotta spend $$ to be cheap.

i have learned a lot and the machine has turned out to be even more useful than I first thought. So it was worth the struggle as it has the smallest footprint and with a bit of thought a lot of capability. If a Darex with an air bearing, or a small Gorton for the same say $800 I would have jumped at them, but they didn’t.

- Joined

- Nov 17, 2019

- Messages

- 22

C-Bag: It's good you got one with R8 because it will be a lot more compatible with your mill. I gather that 5C is pretty much only used with lathes and I find that a mill is four times as useful a lathe for the things I want to make. I'll let you know how my saga comes out. Sounds like you are more than a hobbyist. Do you do jobs for hire or is it all just for fun?

Another one of my passions is WWII history. I think you would find pre-WWII Japan very interesting. One of the controversies over the bombing of "civilians" in Japan and Germany was over the killing of "innocent people". During that time, it was an astounding percentage of their war industry that was contracted out to "hobbyists" like you and me. After Tokyo and other large cities were fire-bombed, the only things left that were recognizable in the after-math in the "residential areas" were a sea of thousands upon thousands of lathes and mills which resisted the flames that annihilated everything else. There were no clear lines between civilians and the war machine in WWII Japan. The machine hobbyist craze of today is an eerie echo of that past.

Another one of my passions is WWII history. I think you would find pre-WWII Japan very interesting. One of the controversies over the bombing of "civilians" in Japan and Germany was over the killing of "innocent people". During that time, it was an astounding percentage of their war industry that was contracted out to "hobbyists" like you and me. After Tokyo and other large cities were fire-bombed, the only things left that were recognizable in the after-math in the "residential areas" were a sea of thousands upon thousands of lathes and mills which resisted the flames that annihilated everything else. There were no clear lines between civilians and the war machine in WWII Japan. The machine hobbyist craze of today is an eerie echo of that past.