Hello folks,

I am new to machining (7x12 benchtop), and I am looking for advice.

I have to tap a hole 35mm deep.

The hole is deeper than the threaded part of the tap's shaft (~25mm).

The shaft is of a larger diameter than the hole.

I want to turn down part of the tap to fit into the hole.

The very first piece of anything I turned was a hardened steel shaft out of a plunge router base.

I used a parting tool to trim off the end with the rough cut.

It was ugly sounding, but worked.

I made the cut dry at a few hundred RPM (no indicator as of yet, so I am guessing).

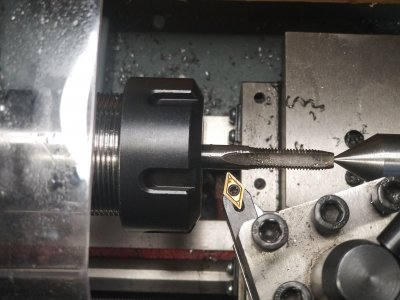

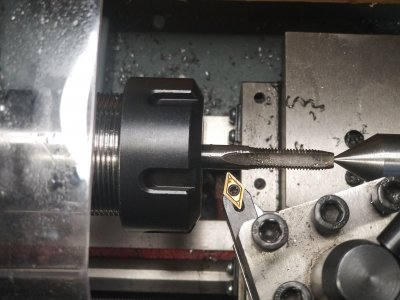

On this tap shaft, however, the flute passes through the cutting path.

This sounded very ugly, and as you can see, I have barely made a mark in the shaft before chipping the carbide insert.

Any suggestions on how I could turn this down would be appreciated.

thanks,

BM

I am new to machining (7x12 benchtop), and I am looking for advice.

I have to tap a hole 35mm deep.

The hole is deeper than the threaded part of the tap's shaft (~25mm).

The shaft is of a larger diameter than the hole.

I want to turn down part of the tap to fit into the hole.

The very first piece of anything I turned was a hardened steel shaft out of a plunge router base.

I used a parting tool to trim off the end with the rough cut.

It was ugly sounding, but worked.

I made the cut dry at a few hundred RPM (no indicator as of yet, so I am guessing).

On this tap shaft, however, the flute passes through the cutting path.

This sounded very ugly, and as you can see, I have barely made a mark in the shaft before chipping the carbide insert.

Any suggestions on how I could turn this down would be appreciated.

thanks,

BM