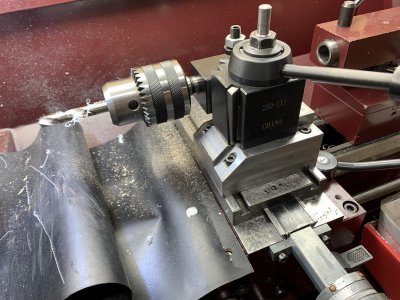

I've been experimenting with the 250-105 on an import 9x20. No compound, though. I'm using a solid tool post. The QCTP held down by the usual stud but there's a dowel and set of grub screws to clamp it square to the spindle. Does not *seem* necessary but without these anti-rotation features, it moves. Also, I had to scrape the bottom of the tool post AGAIN after fixing the QCTP onto it. Unbelievable how much it flexes.

https://www.instagram.com/metatyper/?img_index=1 So in that extreme situation, it works OK. The chuck I have on there is too big and heavy. Check out Gotteswinter's channel for carriage drilling tips. It can be hard to find. Just watch the last 20 videos.

I haven't done any drilling with large drills (0.500 and up). Most of my problems are small drills in deep holes. In that respect, this is much better than my tailstock. For really deep holes, put an O-ring on the drill. Avoids bashing the tip of your drill into the end of the hole.