I've come to the point in my very short CNC career where setting up a tool table is starting to make sense. Since I began CNC'ing I resorted to touching off each tool and resetting Z zero. This works OK but now it's time to move forward. Before crashing and ruining a cutter I thought I'd run my setup past the resident guru's on this site.

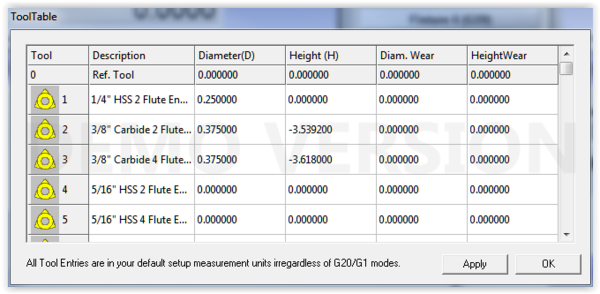

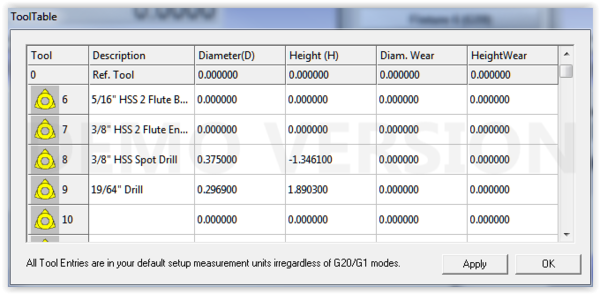

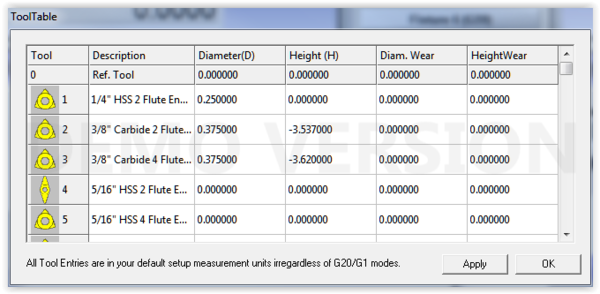

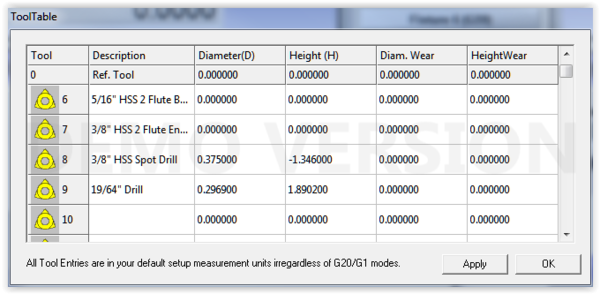

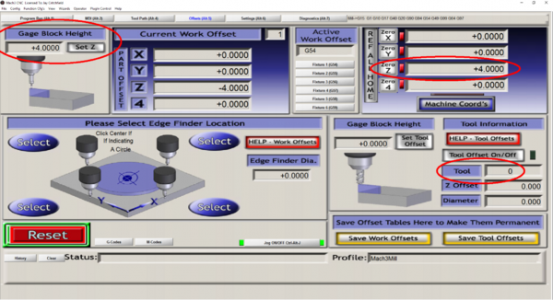

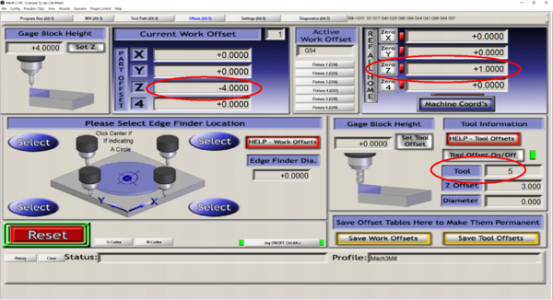

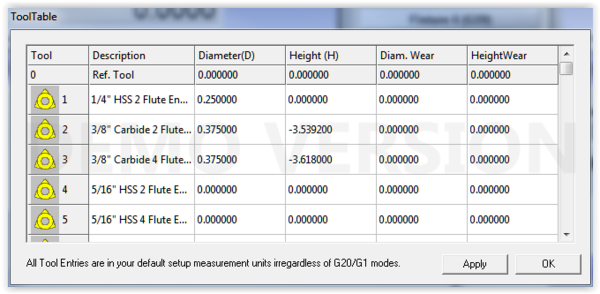

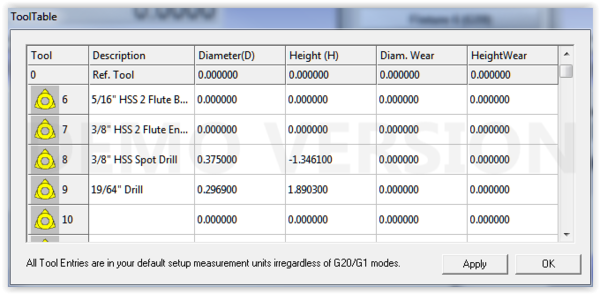

Tools include four cutting tools and a Tool Zero as the reference. I lowered the Tool Zero and touched off on the top of the part and zeroed the Z axis DRO. Loaded Tool 2, touched off on the top of the part and noted the Z axis DRO reading. In this case it was -3.5392. I entered this number in the Tool Table. Followed the same procedure for Tool 3, Tool 8, and Tool 9 and confirmed that the tool offsets were saved (see attached screen shots).

Then I opened the Fusion 360 generated gcode file and changed the "T" number and "H" number to the corresponding tool number in my tool table (sample gcode file attached).

If I'm understanding this process correctly I will touch off Tool Zero and set the Z axis DRO to zero then run the gcode and change the tool as indicated at the M6 command. Am I doing this right? As I said I'd rather ask first before crashing a $40 end mill.

BTW - When I click on the "Help - Tool Offsets" button why does the Z axis move in the "-" direction? Thought it was a help information button and ran the 19/64" drill into the top of the part.

Tom S.

Tools include four cutting tools and a Tool Zero as the reference. I lowered the Tool Zero and touched off on the top of the part and zeroed the Z axis DRO. Loaded Tool 2, touched off on the top of the part and noted the Z axis DRO reading. In this case it was -3.5392. I entered this number in the Tool Table. Followed the same procedure for Tool 3, Tool 8, and Tool 9 and confirmed that the tool offsets were saved (see attached screen shots).

Then I opened the Fusion 360 generated gcode file and changed the "T" number and "H" number to the corresponding tool number in my tool table (sample gcode file attached).

If I'm understanding this process correctly I will touch off Tool Zero and set the Z axis DRO to zero then run the gcode and change the tool as indicated at the M6 command. Am I doing this right? As I said I'd rather ask first before crashing a $40 end mill.

BTW - When I click on the "Help - Tool Offsets" button why does the Z axis move in the "-" direction? Thought it was a help information button and ran the 19/64" drill into the top of the part.

Tom S.