-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Tool Height Tolerance

- Thread starter epanzella

- Start date

- Joined

- Feb 1, 2015

- Messages

- 9,986

There are two angles which are important in determining the performance of a lathe tool; rake and clearance.

The rake angle is the angle between the leading surface of the cutting edge of the tool and a plane through the axis of rotation of the part and the point of contact of the tool. If the leading surface slopes away from the cutting edge, it is a positive rake. A tool can have either back rake, side rake or both.

The clearance angle is the angle between a plane tangent to the part surface at the point of contact of the tool and the trailing surface of the tool. A tool can have either back clearance, side clearance or both.

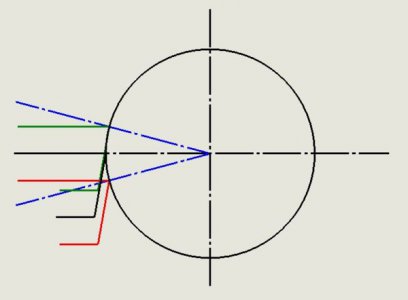

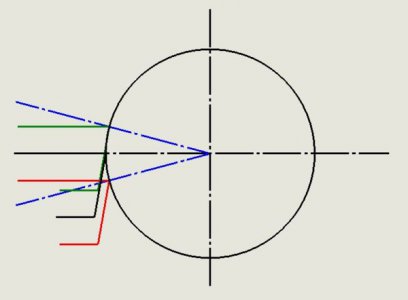

The drawing shows a part being turned with a tool coming in on center (blue), above center (green), and below center (red). The tool is presented horizontally and when on center has zero rake. If the tool is moved to an above center position, the rake becomes positive but the clearance angle is such that there is interference with the work, causing rubbing and a tool the won't cut. If the tool is moved to a below center position the clearance angle has increased but the rake has become negative

Different materials work best within a range of rake and clearance. Here is a site that lists those angles. http://www.steves-workshop.co.uk/tips/toolgrinding/toolgrinding.htm As can be seen, moving a tool up or down from the center line can have a detrimental effect on cutting performance. By grinding a larger rake and clearance angle, the tool becomes less sensitive to vertical position but the strength and durability of the tool is decreased. Furthermore, if you are using insert tooling, you have to work with the geometry purchased.

There are two more reasons for running a tool on center.

First, when off center the angular relationship changes with the part diameter so as a part is being turned down, the rake and clearance are continually changing. In fact, as you are approaching center there will be a point where you are shearing off the remaining nub or riding under it.

Second, machining off the center line distorts the geometry of the cut. The tool moves in a horizontal plane but material is removed radially and the radial motion is the horizontal distance times the cosine of the angle formed by the plane through the centerline and the point of contact and the horizontal plane. And that angle is continually increasing as you get closer to the centerline.

It should be noted that in certain circumstances, it may be desirable to set the tool above or below the centerline as long as proper rake and clearances are observed. There is a complicated mechanical coupling between the work and the cutting tool that will vary greatly from one machine to another. This greatly affects chatter and surface finish. Each setup will have its own sweet spot.

So how accurate do you have to be? A 3º angle has a cosine of .9986 and a sine of .052. On a 1" diameter cut, that would amount to a vertical offset of .026" and the cosine error would be negligible for most work. I use the vertical ruler at times. I also use a gage like this.

https://www.ebay.com/itm/Lathe-Gage...hash=item5649056a5f:m:m3NZb7KTSDbcKWZzGIrJgqA

There are a number of DIY tool height gages which rest on the cross slide. A final check is what happens as the cut approaches the center of the part. If you are low, there will be a nub left or it will break off as you move past center. If you are over, you will shear the nub off.

Edited to include missing drawing

The rake angle is the angle between the leading surface of the cutting edge of the tool and a plane through the axis of rotation of the part and the point of contact of the tool. If the leading surface slopes away from the cutting edge, it is a positive rake. A tool can have either back rake, side rake or both.

The clearance angle is the angle between a plane tangent to the part surface at the point of contact of the tool and the trailing surface of the tool. A tool can have either back clearance, side clearance or both.

The drawing shows a part being turned with a tool coming in on center (blue), above center (green), and below center (red). The tool is presented horizontally and when on center has zero rake. If the tool is moved to an above center position, the rake becomes positive but the clearance angle is such that there is interference with the work, causing rubbing and a tool the won't cut. If the tool is moved to a below center position the clearance angle has increased but the rake has become negative

Different materials work best within a range of rake and clearance. Here is a site that lists those angles. http://www.steves-workshop.co.uk/tips/toolgrinding/toolgrinding.htm As can be seen, moving a tool up or down from the center line can have a detrimental effect on cutting performance. By grinding a larger rake and clearance angle, the tool becomes less sensitive to vertical position but the strength and durability of the tool is decreased. Furthermore, if you are using insert tooling, you have to work with the geometry purchased.

There are two more reasons for running a tool on center.

First, when off center the angular relationship changes with the part diameter so as a part is being turned down, the rake and clearance are continually changing. In fact, as you are approaching center there will be a point where you are shearing off the remaining nub or riding under it.

Second, machining off the center line distorts the geometry of the cut. The tool moves in a horizontal plane but material is removed radially and the radial motion is the horizontal distance times the cosine of the angle formed by the plane through the centerline and the point of contact and the horizontal plane. And that angle is continually increasing as you get closer to the centerline.

It should be noted that in certain circumstances, it may be desirable to set the tool above or below the centerline as long as proper rake and clearances are observed. There is a complicated mechanical coupling between the work and the cutting tool that will vary greatly from one machine to another. This greatly affects chatter and surface finish. Each setup will have its own sweet spot.

So how accurate do you have to be? A 3º angle has a cosine of .9986 and a sine of .052. On a 1" diameter cut, that would amount to a vertical offset of .026" and the cosine error would be negligible for most work. I use the vertical ruler at times. I also use a gage like this.

https://www.ebay.com/itm/Lathe-Gage...hash=item5649056a5f:m:m3NZb7KTSDbcKWZzGIrJgqA

There are a number of DIY tool height gages which rest on the cross slide. A final check is what happens as the cut approaches the center of the part. If you are low, there will be a nub left or it will break off as you move past center. If you are over, you will shear the nub off.

Edited to include missing drawing

Last edited:

- Joined

- Apr 14, 2014

- Messages

- 3,533

Too many people over complicate setting tool height on a manual lathe, especially when using a QCTP. First of all I'll assume you have a properly sharpened HSS tool bit or a new Carbide insert meant for the job at hand. Then just use a straight edge or 6" rule and trap it between the work piece and the point of the tool. If the tool is low the top of the straight edge will tilt toward the operator. If the tool is high the top will tilt away from the operator. Adjust the tool height until the straight edge appears to be perfectly vertical. This simple method will get you within a few thousandths of center.

Next do a face cut on a piece of scrap material. if there is a nub left at the center note whether it's above or below the point of the tool. Adjust in the appropriate direction until no nub remains. Once on center lock the height adjustment nut (or screw). If you're using a lantern post style tool holder this procedure must be repeated anytime you change tooling. When using a QCPT it should be a one time operation until the tool needs to be sharpened or the insert needs to be changed. The object of using a QCTP (quick change tool post) is to make speedy tool changes. If you have a quality system once the tool height is set it should be repeatable every time.

Next do a face cut on a piece of scrap material. if there is a nub left at the center note whether it's above or below the point of the tool. Adjust in the appropriate direction until no nub remains. Once on center lock the height adjustment nut (or screw). If you're using a lantern post style tool holder this procedure must be repeated anytime you change tooling. When using a QCPT it should be a one time operation until the tool needs to be sharpened or the insert needs to be changed. The object of using a QCTP (quick change tool post) is to make speedy tool changes. If you have a quality system once the tool height is set it should be repeatable every time.

Personally I use a tool height gauge all the time because it is easy and a good habit to adopt for consistency. I aim for center unless there is a good reason to stray. For cutting a straight taper, the tool HAS to be dead on center.

- Joined

- Dec 20, 2012

- Messages

- 9,422

To each his own and whatever works, works. I use a gauge and there is no guessing. I don't have nubs or have a need to check for them. You can have a QCTP but the tool holders do not sit at the same elevation every time you seat them in the post; you're fooling yourself if you think they do.

- Joined

- Oct 3, 2015

- Messages

- 1,010

I turn lots of rifle barrels, and a dead centered tool will leave you with a mess. I run .015" doc, and .015" pr with a ccmt insert oriented like this ^, and run the tool high as I can get it and still cut. It might even squeal at the beginning of the cut, but if you don't, there will be chatter so bad in the middle section, it will look like rope.

I know that a lot will depend on the individual machine, but I turned hundreds of barrels without a steady or follower rest using this method.

I know that a lot will depend on the individual machine, but I turned hundreds of barrels without a steady or follower rest using this method.

- Joined

- Dec 20, 2012

- Messages

- 9,422

I turn lots of rifle barrels, and a dead centered tool will leave you with a mess. I run .015" doc, and .015" pr with a ccmt insert oriented like this ^, and run the tool high as I can get it and still cut. It might even squeal at the beginning of the cut, but if you don't, there will be chatter so bad in the middle section, it will look like rope.

I know that a lot will depend on the individual machine, but I turned hundreds of barrels without a steady or follower rest using this method.

Interesting to read this, @derf. @Bamban also reported having better finishing results with an increased lead angle on his insert when doing barrels. I use a CCMT/CCGT insert in a 3/8" tool holder and found that raising the tool 0.005" above center cut better for me with deeper depths of cut. I'm pretty sure this counters tangential forces in a similar fashion that raising a boring bar up does. I also angle my cutter like you and Bamban do when doing finishing cuts, especially in aluminum, and get much better finishes. My thinking is that raising the cutter above center reduces tangential forces and angling the cutter reduces radial forces so the cut is more accurate with a better finish. It isn't necessary to angle the cutter for deep cuts but it sure helps finishing cuts, at least for me. Now that makes three of us who don't use inserts the way we're "supposed to".

It is curious that you can cut a long barrel without a taper without follow rest support. I'll have to try it and see how it works.