- Joined

- Jun 7, 2016

- Messages

- 361

Hi Ted

Thanks for your comments. When I got my first lathe, a smallish one (38mm spindle) - I did little homework, I just thought I could turn up some spacers and bushes and aligning tools for working on my old bikes.

The lathe had 12mm tooling, so not too expensive and I just drifted into insert tooling. So I made stuff and had a lot of fun with the machine - it did so much work I had to replace several bearings which had worn out (all be it, they were probably cheap Chinese bearings) - but eventually I got frustrated with a machine that had no threading dial, had manual change gears - so power feeding largely got ignored - and other things.

So now I am starting again with a new lathe (arriving soon I am told - we will see) -

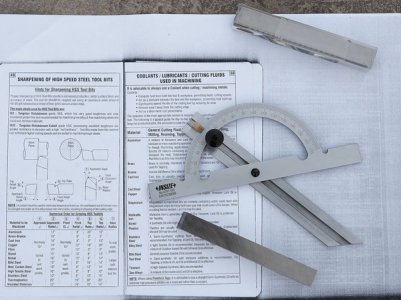

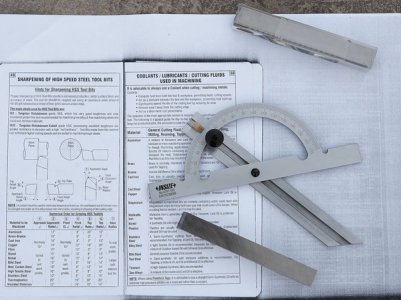

I ducked over to my local supplier and picked up some HSS (8% cobalt) blanks and I have a small engineers protractor for the angles.

Now for some rough grinding while I wait for my replacement white stone grinding wheel. This time around I will put my nose to the metaphorical grindstone and be a lot more particular about, ground angles on the tooling, feed rates and of course the final arbitrator - chip formation, surface finish and accuracy.

Cheers

Mal

Thanks for your comments. When I got my first lathe, a smallish one (38mm spindle) - I did little homework, I just thought I could turn up some spacers and bushes and aligning tools for working on my old bikes.

The lathe had 12mm tooling, so not too expensive and I just drifted into insert tooling. So I made stuff and had a lot of fun with the machine - it did so much work I had to replace several bearings which had worn out (all be it, they were probably cheap Chinese bearings) - but eventually I got frustrated with a machine that had no threading dial, had manual change gears - so power feeding largely got ignored - and other things.

So now I am starting again with a new lathe (arriving soon I am told - we will see) -

I ducked over to my local supplier and picked up some HSS (8% cobalt) blanks and I have a small engineers protractor for the angles.

Now for some rough grinding while I wait for my replacement white stone grinding wheel. This time around I will put my nose to the metaphorical grindstone and be a lot more particular about, ground angles on the tooling, feed rates and of course the final arbitrator - chip formation, surface finish and accuracy.

Cheers

Mal