- Joined

- Feb 8, 2014

- Messages

- 11,176

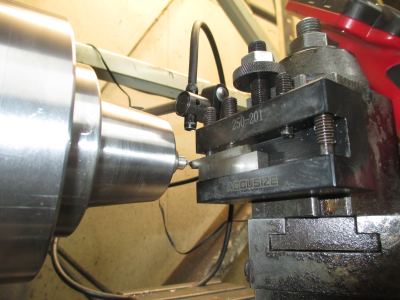

I am making some tiny parts for a customer. What I really want to show here is my setup. They are so small I can't really see what I am doing so my HF inspection camera came to the rescue. Not as much magnification as I would like, but better than my eyeballs and I don't have to have my head down into the works to see it. I wish I had a Hardinge HLV-H toolroom lathe to do stuff like this. But between the HF camera, and the DRO, it works.

I can't actually show the parts due to NDA's, but I can say that they are about 9/16 long and the smallest diameter is about 0.070 Made of 5/8 dia, 303 SS. Could have used smaller material to start with, but I had 5/8 on the shelf. Only takes a couple of minutes to turn it down to the rough size. Holding +0 / -0.0002 on the ODs Final dimension is done with 1000 grit emery and a small file as a backer. The next step in the process is drill & tap a M1.2x0.25 hole in the end. The taps & drill bits look like sewing needles. I'll show that setup when I get to it.

I'm going to buy one of these video microscopes for the next time I do a project like this. https://www.amazon.com/Digital-Micr...41&sprefix=digital+microscope+,aps,211&sr=8-3

These pictures are part way through the roughing out process and don't show any part detail. There are several features that need to be machined into the OD. That tool bit is 0.031 wide. Done on my Jet 13x40 lathe.

I can't actually show the parts due to NDA's, but I can say that they are about 9/16 long and the smallest diameter is about 0.070 Made of 5/8 dia, 303 SS. Could have used smaller material to start with, but I had 5/8 on the shelf. Only takes a couple of minutes to turn it down to the rough size. Holding +0 / -0.0002 on the ODs Final dimension is done with 1000 grit emery and a small file as a backer. The next step in the process is drill & tap a M1.2x0.25 hole in the end. The taps & drill bits look like sewing needles. I'll show that setup when I get to it.

I'm going to buy one of these video microscopes for the next time I do a project like this. https://www.amazon.com/Digital-Micr...41&sprefix=digital+microscope+,aps,211&sr=8-3

These pictures are part way through the roughing out process and don't show any part detail. There are several features that need to be machined into the OD. That tool bit is 0.031 wide. Done on my Jet 13x40 lathe.