- Joined

- Sep 8, 2019

- Messages

- 4,392

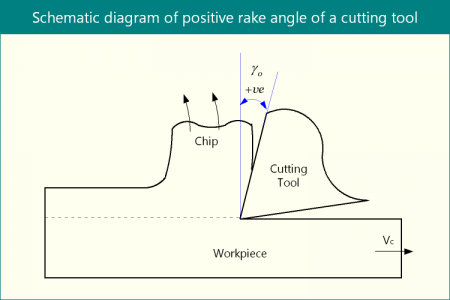

Yes, if the particular lathe is up to it, carbide can speed metal removal, but I see all to many folk using negative rake tools on low power/rigidity machines because they esteem how many cutting edges that they may offer rather than how well they preform under the conditions that the machine may provide; forget about how many edges are offered, concentrate on how freely they cut.

The carbide is appealing because (1) you know the cutting geometry is spot on (this shows my level of confidence in my HSS grinding skills), (2) faster work via higher RPMs, (3) faster work via deeper cuts, and (4) faster work via switching out a dulled cutter.

Of course, the smaller the lathe, the less likely we are able to capitalize on the benefits above.

To HSS’s credit, it can offer better economy, the ability to grind a custom cutter, improved performance on smaller machines, and nostalgia.

Both HSS and carbide can achieve the same level of quality work.

Maybe a particular machinist’s choice of carbide vs. HSS is a reflection of (1) how large their lathe is, (2) how much of a hurry they are in, and (3) which type of cutting material they are used to working with.

Last edited: