That view looks better.

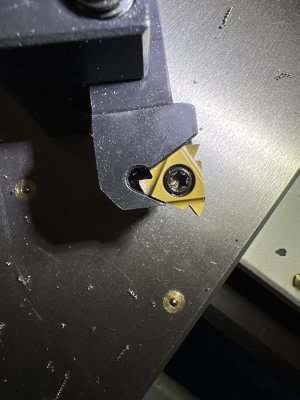

For turning, carbide definitely likes fast speeds. For that diameter stock, I would be in the 1200+ range with the inserts I have. I use TNMC inserts for external threading, they are on edge style, but seem to work fine in the 200-300 rpm range. I started with the Arthur Warner HSS inserts mentioned earlier and recently switched to carbide since the holder I bought came with one, and it seemed to worked at the lower speeds as well, but did improve a bit more as the speeds got higher. You could try going faster, if your reflexes can keep up, and see if that helps. It could also be the insert from the kit, I’m assuming the insert is from the kit you posted earlier, is not that good and a name brand insert would work better.

If you have some larger diameter stock you can try on, that will give you a higher SFM without speeding up the machine to the point you can’t keep up and you will see if the higher surface speed helps.