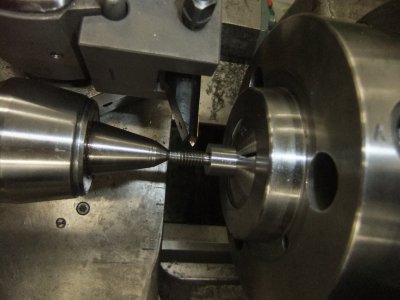

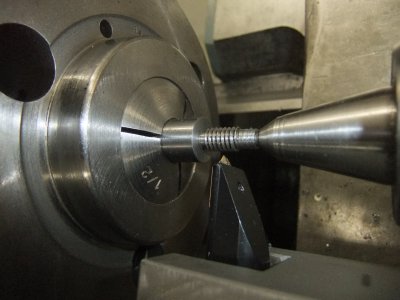

Single point threading ¼” crs can be too much “tool pressure” for the billet material when length from the chuck becomes 3 X diameter. The material will flex and then push away from the tool, roll on top of the threading tool and then bend. Solution: use a die, geometric die head, use a center when threading it, use a follower rest, roll the threads, or? Can you use all thread and Loctite the threaded rod into the project?...Good Luck, Dave.