- Joined

- Feb 1, 2015

- Messages

- 9,978

RJ,

Thank you for your patience and help.

Unfortunately my spindle does not have a groove and there may not be enough space to make one.

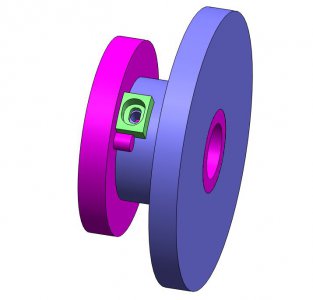

BamBam, It's hard to see from your photo but I was thinking of something a long the lines of a set of pins on the face of the spindle with a lock screwed into the hub of the backplate. The drawing below shows the thought. The spindle face (magenta) would have two pins added (e.g., cap screws threaded in 180 deg. apart. The backplate (purple) would have two holes threaded in. Two stops (green) would be screwed to the mounted backplate so they are touch in the pins on the spindle. The holes in the hub would be located after mounting the backplate. Since the mounted position is essentially the same each time the chuck is mounted, very little allowance for variation need be made. The elongated slot should be sufficient.

Bob