-

Welcome back Guest! Did you know you can mentor other members here at H-M? If not, please check out our Relaunch of Hobby Machinist Mentoring Program!

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

The PM-1236T vs PM-1340GT dilemma

- Thread starter litewings

- Start date

- Joined

- Jun 12, 2014

- Messages

- 5,055

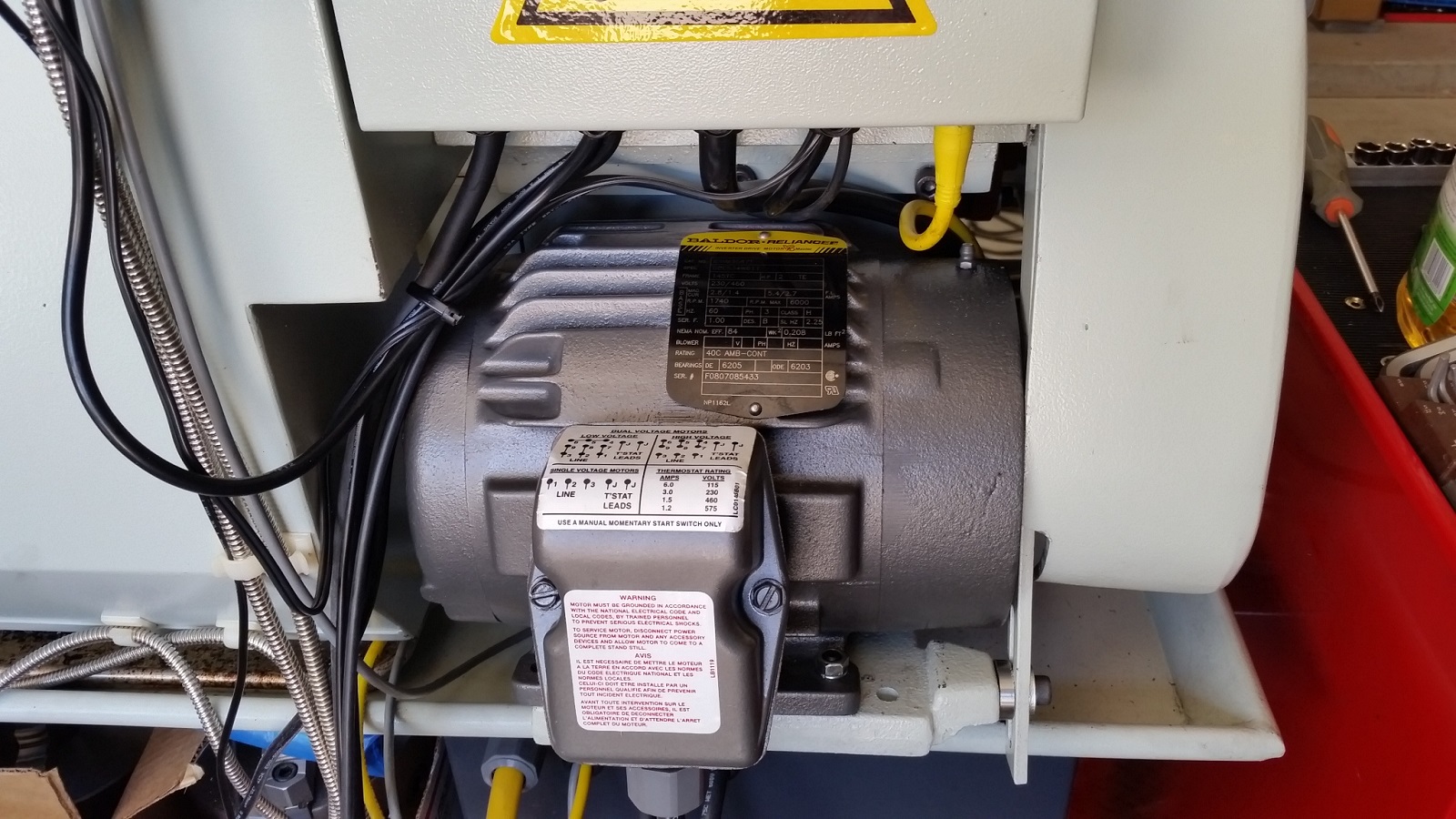

A VFD conversion does not use the electrical cabinet contactors to switch the motor wires, the motor is directly connected to the VFD. See the "basic 1340GT VFD conversion" thread for details of how this is done, also QMT has some info they provide. The motor space is very limited in the 1236/1340GT models there are only a few TENV motors with a 145 frame size that will fit, a TEFC will not fit. The stock 2 Hp motor is quite decent and provides plenty of usable speed range, typically 20-100 Hz, I also recommend flipping the motor pulley and running it from the large motor pulley to the large headstock pulley (requires a longer belt) and running the belt as a single belt speed. Since you have a 6 speed headstock, you do not need extend the motor speed range. If one wanted to replace the stock motor then you would need to replace the motor pulley anyway with a 2.4-2.6" single pulley (stock is 3/4" and most 145 frame motors are 7/8"). You would run the inverter/vector motor from 20-125 Hz. Worthwhile if you have a single phase motor, not so cost effective if you have the stock 2 Hp 3 phase motor. You gain a bit more usable speed range and the speed stability running the VFD in sensorless vector mode you go from +/-5 RPM to something like +/-1 RPM speed variation. So the stock motor is pretty decent and works well paired with a decent quality VFD.

The alternate motors has been previously outlined, you can do a search example:

www.hobby-machinist.com

"If going to a 3 phase motor, there are a very limited number of 2Hp 3 phase motors that will fit, and they all require some redrilling of the mounting holes motor/mount to fit and a different pulley (or bore the stock one to 7/8"). These motors are all TENV, these are ones that others have used Marathon E467, Y551, Y526. The Y551 and Y526 have a small encoder shaft on the back of the motor that needs to be cut off." In addition the Baldor IDNM3587T if you can find one inexpensively, the back encoder shaft is cut off with a hacksaw, you may also need to do some trimming of the belt cover. All these motor conversions were done on the 1340GT, not sure if the 2 Hp will fit on the 1236GT, as you can see it is a tight fit. I would use the stock 3 phase motor first and then see if you want to switch it out, at the end of the day individuals tend to overthink all the what if's before they actually start using the lathe. I would use the Hitachi WJ200-015SF VFD which is 2 Hp for all these motors, it works well and there is a lot of experience using the it.

www.hobby-machinist.com

"If going to a 3 phase motor, there are a very limited number of 2Hp 3 phase motors that will fit, and they all require some redrilling of the mounting holes motor/mount to fit and a different pulley (or bore the stock one to 7/8"). These motors are all TENV, these are ones that others have used Marathon E467, Y551, Y526. The Y551 and Y526 have a small encoder shaft on the back of the motor that needs to be cut off." In addition the Baldor IDNM3587T if you can find one inexpensively, the back encoder shaft is cut off with a hacksaw, you may also need to do some trimming of the belt cover. All these motor conversions were done on the 1340GT, not sure if the 2 Hp will fit on the 1236GT, as you can see it is a tight fit. I would use the stock 3 phase motor first and then see if you want to switch it out, at the end of the day individuals tend to overthink all the what if's before they actually start using the lathe. I would use the Hitachi WJ200-015SF VFD which is 2 Hp for all these motors, it works well and there is a lot of experience using the it.

With the 1340GT you get better a much better chuck, with the PEP package, so you are looking at a 1K difference if you take out the chuck. The 1236 comes with an "economy chuck", you get what you pay for, it would be the first thing that would become a doorstop for me. Start adding a motor, your time, etc. and the difference becomes smaller. Then, start adding up all the tooling/chucks, which would be the same for 1236/1340GT and it all adds up quickly, the overall cost difference becomes smaller.

The alternate motors has been previously outlined, you can do a search example:

1340gt surface finish problem

I figured out how to get into Super Macro mode, these aren't very good but they're closer:)

www.hobby-machinist.com

www.hobby-machinist.com

With the 1340GT you get better a much better chuck, with the PEP package, so you are looking at a 1K difference if you take out the chuck. The 1236 comes with an "economy chuck", you get what you pay for, it would be the first thing that would become a doorstop for me. Start adding a motor, your time, etc. and the difference becomes smaller. Then, start adding up all the tooling/chucks, which would be the same for 1236/1340GT and it all adds up quickly, the overall cost difference becomes smaller.

I'm going through this same thing right this second. The only difference between the two is the weight, size, gears, and warranty. Matt said the 1236T with 3ph motor is the exact same 2hp that is on the 1340. I priced them both out with accessories, a DRO, and the same 3 jaw that comes with the 1340 PEP and its about a $1,000 difference. I don't think I'll EVER need those 4 inches, but my stupid male mind says I have to have the bigger one and hardened gears. My sense tells me to save my $1,000 because I'll probably never notice the difference in use. ARGHHHH!!! I want to tell Matt today.

- Joined

- Jun 12, 2014

- Messages

- 5,055

I was not aware that it is the same motor, the spec's say 1.5 Hp on the 1236GT and 2.0 Hp on the 1340GT. The 1340GT will have a little more swing, and probably fit oversized QCTP holders with 3/4" holders. I did use some 3/4" holders on my 1340GT. Not sure anybody is going to wear out the gears in their lifetime, but if you are doing more high speed work it may be give you more peace of mind with hardened gears. Not sure as to what comes with the PEP packages, stands, etc. Also inventory, as it seems numerous models from different manufactures are on back order and I would expect longer than usual delays. There are a few other upgrades to consider such as Chandox set-tru chuck, Aloris QCTP, etc.

I probably would opt. for the 1340GT if this is going to be a long term keeper, save some money on doing some things yourself (like installing a DRO if you go that route). Look at spreading out getting additional tooling accessories.

I probably would opt. for the 1340GT if this is going to be a long term keeper, save some money on doing some things yourself (like installing a DRO if you go that route). Look at spreading out getting additional tooling accessories.

I was not aware that it is the same motor, the spec's say 1.5 Hp on the 1236GT and 2.0 Hp on the 1340GT. The 1340GT will have a little more swing, and probably fit oversized QCTP holders with 3/4" holders. I did use some 3/4" holders on my 1340GT. Not sure anybody is going to wear out the gears in their lifetime, but if you are doing more high speed work it may be give you more peace of mind with hardened gears. Not sure as to what comes with the PEP packages, stands, etc. Also inventory, as it seems numerous models from different manufactures are on back order and I would expect longer than usual delays. There are a few other upgrades to consider such as Chandox set-tru chuck, Aloris QCTP, etc.

I probably would opt. for the 1340GT if this is going to be a long term keeper, save some money on doing some things yourself (like installing a DRO if you go that route). Look at spreading out getting additional tooling accessories.

Matt said the 1.5hp is the single phase but the 3ph comes with the 2hp. I’ve pricedthe 1236T with the same chuck as comes in the 1340 PEP and still about a grand difference. I’ll only ever be an occasional user so I doubt I’ll wear out the gears and I cut primarily stainless steel and titanium at slow speeds.

What do you mean by Aloris QCTP, the 1340 doesn’t come with that, does it?

I was in this exact same place last fall, paid the extra and went with the 1340. My logic: This is the last lathe I will ever buy. I've never been upset or disappointed because I bought "too good" of a tool. My brother, gift yourself what you really want.I'm going through this same thing right this second. The only difference between the two is the weight, size, gears, and warranty. Matt said the 1236T with 3ph motor is the exact same 2hp that is on the 1340. I priced them both out with accessories, a DRO, and the same 3 jaw that comes with the 1340 PEP and its about a $1,000 difference. I don't think I'll EVER need those 4 inches, but my stupid male mind says I have to have the bigger one and hardened gears. My sense tells me to save my $1,000 because I'll probably never notice the difference in use. ARGHHHH!!! I want to tell Matt today.

Lol! You guys aren’t making me feel better about trying to save money! Though I do appreciate the honest advice. Matt keeps telling me to get the 1236T. He says there is no rigidity difference and the both perform the same. He said he has an older 1340 without the hardened gears they use every day and it still looks like new. He said the only real reason to get the 1340 is if you need the extra 4”. Need them? Probably not, but my man instincts tell me I do.